Imagine you’re on a Boeing 767 with 199 fellow passengers. As the plane taxis to the destination gate, the purser turns on the intercom and says, “Please remain seated until we unload our in-flight casualty.” Then the plane docks, the door opens, and a paramedic team rushes in and quickly evacuates the injured passenger.

If this scenario actually happened on the average airline flight, how successful do you think these flights would be from a passenger point of view?

Do the math and you could say pretty successful. After all, 99.5 percent of the passengers arrive intact and undamaged. Only .5 percent have a problem – which equates to a load damage rate of only .5 percent. Not too shabby. But would it be fair to say a better scenario would be for all passengers to arrive intact and undamaged on all flights?

When we’re accustomed to a load damage rate close to 0 percent – which is what the airlines actually deliver – .5 percent is a lot. It means that on the average, one passenger in 200 would be hurt or damaged on every flight. Most of us would probably agree that this is an unacceptable level of risk.

Shipping Damage Steals .5 percent of Your Gross Sales

But what’s unacceptable for one transportation mode could be the norm for another. The Grocery Manufacturers Association and the Food Marketing Institute tell us, for instance, that shipping damage (damage that happens between the factory and the point of sale) for the food, beverage, and consumer products industries averages about .5 percent of gross sales.

The bad news is this amounts to about a billion dollars a year of damage losses in the U.S. alone. The good news is that much of this damage can be avoided.

Standard Practices Reduce Shipping Damage

By making us put our tray tables and seat backs in the upright position for take offs and landings, making us fasten our seat belts when we’re seated, and limiting our movement about the cabin while in flight, airline companies have eliminated their “shipping damage.”

Shipping pallets of products poses a different set of damage problems. But like injuries to airplane passengers, they’re problems that can be avoided by using standard processes.

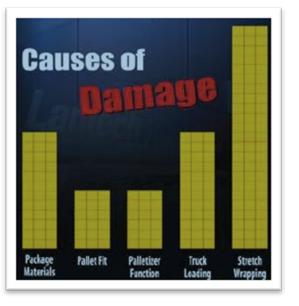

Here are the major causes of shipping damage to loads:

- Creating package instability by reducing materials in primary packages.

- Building loads that don’t fit their pallets.

- Using palletizers that build loose or irregular loads.

- Loading trucks too tightly or leaving gaps between loads

- Poor stretch wrapping.

Better Stretch Wrapping is the Best Way to Start Reducing Damage

Of these causes of damage, stretch wrapping is the easiest, fastest and least expensive way to decrease damage. And if that’s not enough, more effective stretch wrapping is also the “low hanging fruit” or the “band aid” for mitigating or compensating for the other major causes of damage.

If you’re shipping stretch wrapped loads, unless you have evidence to the contrary, you’re not doing better than a 99.5 percent success rate. And even if you’re hitting 99.5 percent, it’s not good enough. You’re averaging $50 to $500 damage per truckload and leaving money on the table.

Or put another way, a $100 million company loses $500,000 a year in avoidable shipping damage. How much does it have to sell to make up that loss?

Reduce Your Shipping Damage by 50 percent.

Stop wasting money. There’s low hanging fruit to be picked. One half a percent damage doesn’t have to be your norm. Lean processes and principles typically reduce damage and waste by 50 percent or more wherever they’re applied.

Get a copy of our 10 Step Process for Damage Reduction Through More Effective Stretch Wrapping and take the first steps toward driving down your shipping damage and begin recovering lost dollars now.

Click here to read related blog: How Did We Miss This?

This post was published on June 18, 2014 and updated on July 20, 2015.

June 18, 2014