Step 1: What is Containment Force?

At its most basic, Containment Force is the hugging pressure that holds your load together. Containment Force is the result of the number of revolutions of the stretch film multiplied by the wrap force (tightness). It’s the key specification in reducing damage and ensuring safe to ship loads. You’ll need to do testing and checking to discover your ideal Containment Force. However, when measuring Containment Force, you should check three places on a wrapped load to make sure we have the right amount of force throughout the load.

Here’s how that process might look.

Here’s how that process might look.

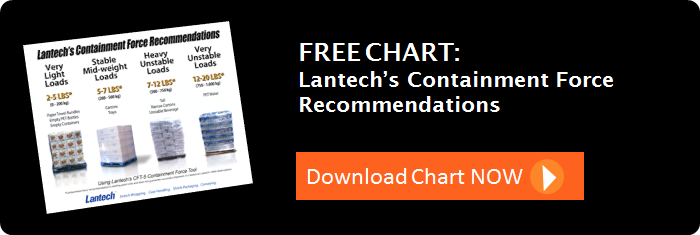

Let’s start with a fairly stable load; it weighs 2,000 pounds and is 5 ft. tall. We have determined, thanks to our Containment Force Recommendations Guide, that we need a minimum of 10 pounds of Containment Force to safely ship this load. Using our CFT-6 Containment Force tool, we measure three areas — top, middle and bottom — and find the following:

- Top: 7.5 pounds

- Middle: 3.5 pounds

- Bottom: 8.2 pounds

Clearly, this is not enough. Remember, on this load we need at least 10 pounds everywhere for a safe to ship load.

How do you change Containment Force?

We can increase our numbers by increasing either the wrap force or number of revolutions of film.

Adding more revolutions of film can increase costs, so we want to see if we can increase the wrap force first. If it’s not possible, then we need to increase the revolutions.

We’ll increase the wrap force by turning it up. If the film breaks, or the load twists or shows sign of crushing, we’ve wrapped it too tightly, and we need to back it down. But in this case, we’ll assume none of these happened, so we increase the wrap force and come up with this:

- Top: 10.3 pounds

- Middle: 8.5 pounds

- Bottom: 10.9 pounds

That’s better. We’re getting closer to our goal. But we want a “10” throughout. To achieve this we could add more revolutions to the middle of the load to get to 10 or more pounds of containment force. That will add to the total amount of film used. The point is, we have choices in reaching our desired Containment Force.

Once we have all our settings where we want, we can run as many of these loads as necessary before switching out to a new load, and starting the process all over.

How often should you measure Containment Force?

Finally, it’s important that you measure the Containment Force of your loads periodically. While this is ideally a set-and-forget type of operation, you never know if the settings were accidentally changed or if there’s a part that needs maintenance. New technology is available on automatic stretch wrappers that will measure every load, every day to make sure your loads are getting the proper amount of Containment Force. If you don’t have machines that check for you, check your Containment Force at least once per shift to make sure you’re doing all right.

Check out these related posts on Containment Force:

- Use The Force: Containment Force Is The Key to Safe Pallet Loads

- 6 Common Semi-Automatic Pallet Wrapper Safety Considerations

- Pallet Jack Safety Fails: An Infrequent But Serious Problem

This post was published on September 12, 2016 and updated on February 13, 2019.

September 12, 2016

Here’s how that process might look.

Here’s how that process might look.