Turning to the Forklift Boss….

Marshall Cromer writes a periodic blog on forklift topics. It’s a good source for some insights into forklift operations and budgeting. In a recent series he covered:

- How to Buy a Forklift – seven planning guidelines

- What does your forklift cost to run/hour – with an explanation of why $4/hour in maintenance may be the key factor in gauging when it’s time for replacement

- How electric forklifts save money on fuel & maintenance – a deep dive into the cost implications of different power options

On the one hand, we know that in many factories, forklifts are just sort of assumed or expected to work much like pallet wrappers. On the other, this is a good reminder that there’s lots of detail behind how the pallet get’s loaded onto a wrapper and a lot for warehouse and logistics teams to manage. And there’s another angle that caught our attention – hidden costs. That’s applicable throughout warehouse operations.

The right lift for the application

Members of our Lantech team are on a lot of loading docks and in a lot of warehouses. We’re also in freezers, wandering distribution centers and even in storage yards. So while we’re not forklift experts like Marshall, we understand that big tires, heavy lift capability and diesel power are common attributes of lifts used by our construction products customers who move building materials, bark mulch and other related products. In contrast, small, nimble, quiet electric trucks are often used by our pharmaceutical industry customers. (Find more on your industry here. For instance, why dirt and dust complications with powered turntables may mean straddle wrappers are better for building products – and why heat sealing film tails can be important for products that are loaded on flatbed trucks for highway transportation.)

Cromer’s “How to Buy a Forklift” article provides some common sense guidelines that are applicable across industries.

Beyond the capital cost

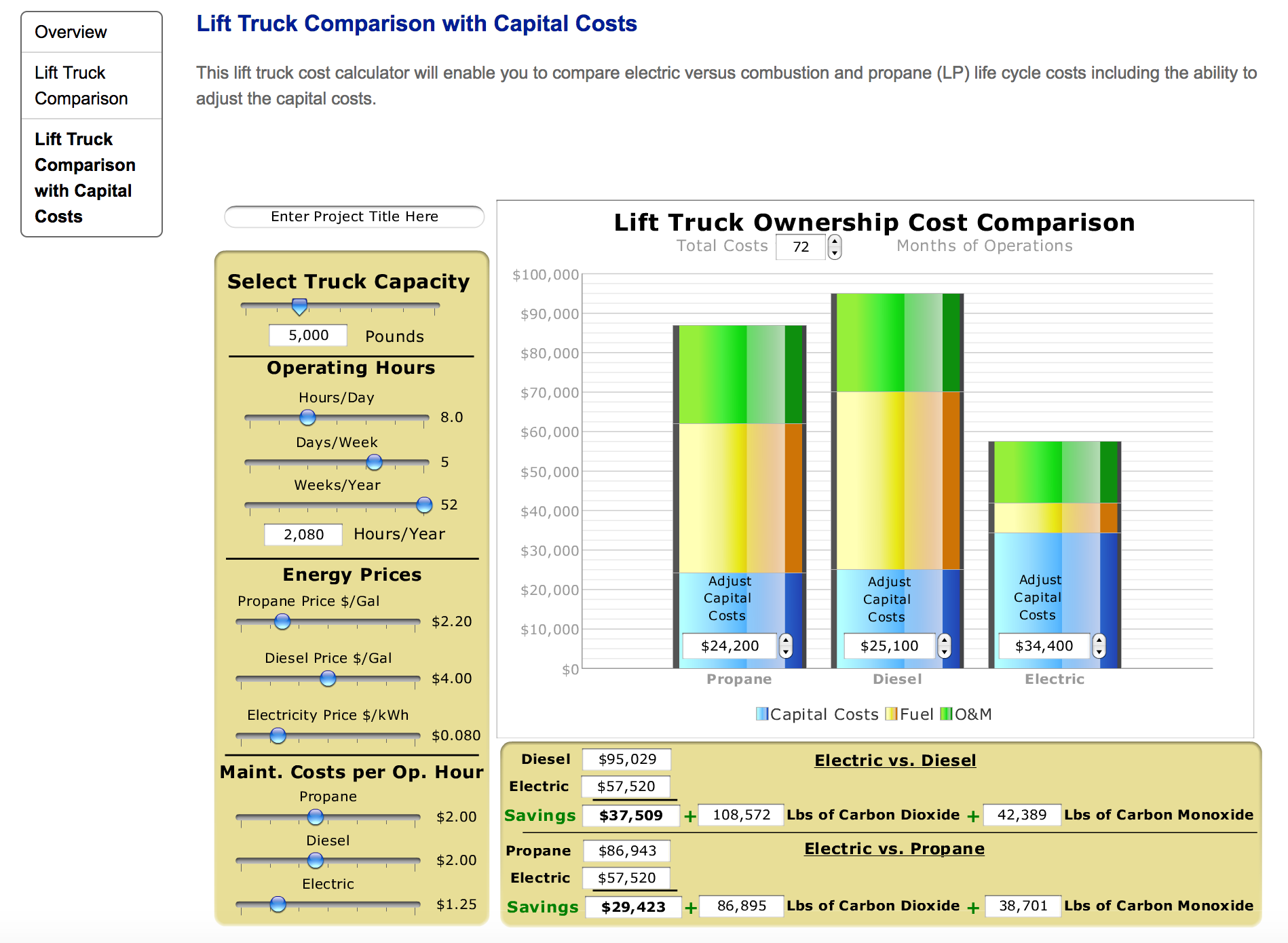

While the EPRI calculator is specific to forklifts, the principle certainly isn’t. There are costs of ownership and operation that are often overlooked.

Capital equipment buyers have been conditioned to consider the total cost of ownership (TCO) for a number of years. Replacement parts, warranty, the economy of consumables, and likely lifespan are often weighed in even rudimentary machine procurement processes.

But there’s another category of cost that’s less frequently considered.

Efficiency of Operation

In its sophisticated form, this may be a comprehensive OEE (overall equipment effectiveness) metric. However, it can be substantially simpler.

In the case of fork trucks, the charge time for batteries can be weighed against the cost of additional batteries and time of operation on a charge. Yet as Cromer notes in one of his articles, electric drive eliminates the maintenance cost, parts, and downtime associated with combustion engines. There are trade-offs.

Pallet wrappers obviously have different factors, but the principle is the same. Film breaks are one of the most pernicious causes of downtime. Often each incident is a seemingly insignificant minute or two – hardly enough to worry about. But over shifts, weeks, months and years the net impact on throughput can be significant. But that’s not all….the most common reaction to frequent film breaks (particularly if “purchasing bought new film that’s supposed to be the same”) is to reduce film tension or to discard film rolls that haven’t been completely run.

Wondering how to optimize your forklifts? The Forklift Boss might have some answers. Wondering how to optimize your stretch wrapping? Register for our free 30-minute webinar – “How to Fix Common Wrap Problems.”

This post was published on December 12, 2016 and updated on February 13, 2019.

December 12, 2016