Buying Your First Stretch Wrapper

Here are some tips and information to help you navigate the buying criteria and buying process for your first semi-automatic stretch wrapper.

Up Front Costs

We know from experience that most companies build stretch wrappers into their budgets, so here’s some information to help you do that. If you need something specific or need it in a hurry, you can call us at +86 40 0877 1972 or you can request a quote here.

The math is pretty simple, though. Generally, a semi-automatic turntable pallet wrapper costs around $9,500 to $17,000. Freight charges range from $800 to $1,400 depending on your location and our local distributor partners typically perform start-up and training for an additional cost.

Straddle wrappers are a bit more expensive and cost around $17,000 to $24,000. Freight is similar as are start-up and training costs, but assembly and installation are required for these machines. The buyer is responsible for that task and cost.

Charges vary depending on geographical location and nature of the facility. Our distributor partners can either install it for you or help you find a qualified third party if you don’t want to do the work yourself.

So for budgetary planning the range is somewhere between $11,500 to $25,500. Want a more specific number? Then simply request a quote or call us at +86 40 0877 1972.

Ongoing Savings

Companies are often really surprised at how much they can save. A typical company wrapping 50 loads/day by hand spends about $7,000 to $15,000 year on film and invests in 850 to 1,000 hours of labor to wrap those loads.

By transitioning to machine wrapping we’re able to reduce film costs by roughly half to two thirds. That means an average company could recover about $3,500 to $6,500 a year in wasted film!

Then, there’s the huge savings in labor – and injuries – that could reduce turnover. No longer are your workers wandering dizzy around pallets.

- Using a machine to stretch wrap pallets frees them up to work on other priorities and, in turn, helps you contain costs.

- Some of the highest rate of incidence for workplace injuries are warehouse jobs that require bending and lifting, hand wrapping for example.

A wrapper can drive savings by reducing or eliminating those risky roles.

Options

Ever buy a machine and then afterwards wish you’d known about some critical capability beforehand? Check out options to consider.

Do I have to buy options with the machine? There are a lot of retrofitable upgrades, so many machines can be field adapted. But most are less expensive when built into the wrapper originally. So if your requirements suddenly change, then our flexible retrofits will be a great resource for you. But if you think you might need a bit more, then it’s usually better to order it when you buy the machine.

What are common options?

- Mast height extensions to wrap taller loads

- Ramps for loading turntable wrappers with pallet jacks

- EZ Weigh™ Integrated Scale

- Auto Film Cut-off®

- Pallet Grip®

Different goals or requirements?

As often as we see common goals for new wrappers we know that every company is different. Are you considering stretch wrapping as a solution to another challenge? Please give us a call at +86 40 0877 1972.

We’ve seen MANY different scenarios and might have a specific example that’s relevant to help you as you plan.

Other Resources

3 Things You Must Know About Stretch Wrapping

This infographic is a nice reminder that just because there is film around a load, doesn’t mean it is safe-to-ship. Print out this poster to remind yourself of the downside of poorly wrapped loads.

Benefits of Machine Stretch Wrapping eBook

If you’re looking to improve your loading dock operations, download this eBook to understand how stretch wrapping with a machine can drive economical, efficient and ergonomic improvements.

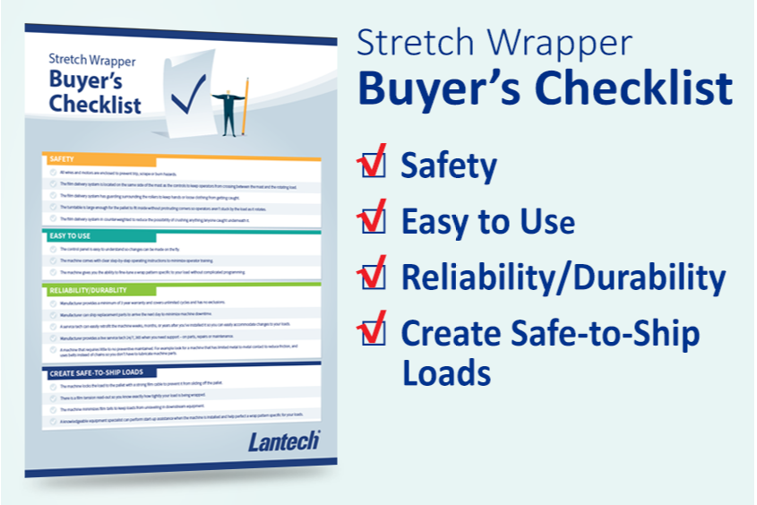

Checklist for Buying a New Stretch Wrapper

An ounce of prevention comes in the form of doing your research before you buy a new machine. Use this checklist as a guide when making your stretch wrapper purchasing decision.