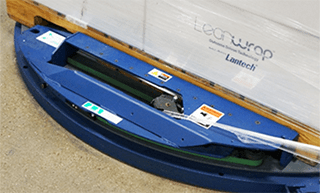

S Semi-Automatic Stretch Wrapping Equipment

Perfect for order-picked, heavy or unstable loads

Models

Lantech S Series semi-automatic stretch wrappers are designed for a wide variety of applications. Because this machine is floor-loaded and applies film with a wrap arm, it is particularly ideal for order-picked, unstable or extremely heavy loads.

Advantages

Lantech packaging equipment is a notch above the rest. Our semi-automatic stretch wrappers are easy to use, safe and reliable. See all of the advantages to choosing Lantech S semi-automatic stretch wrappers including video evidence.

Productivity Enhancements

Work smarter, not harder. Lantech offers productivity enhancing features on our S Semi-Automatic stretch wrappers that help you do more with less. Save 2 minutes of labor per load and keep your driver on the forklift with the XT and Click-n-Go.

Need help choosing the right machine for your application?

Perfect for the eCommerce, Distribution and Logistics Industries

Shipping environments with varying load configurations require an easy to use stretch wrapper that will wrap a safe-to-ship load every time. The S Semi-Automatic straddle stretch wrapper meets these requirements. Designed specifically for order-picked or unstable loads, common in the eCommerce, distribution and logistics industries, loads are placed on the floor and a wrap arm rotates around the pallet to apply film. With this stretch wrapper there is no weight restrictions. It can be loaded with a forklift, pallet jack or walkie-rider and unstable loads are not at risk of falling apart at the stretch wrapper.

Comparing equipment? We have several resources to help you select the right machine for your application.

Visit our Stretch Wrapping Resource Section

Why Choose Lantech Stretch Wrappers

Reliable

Don’t go down because of inadequate equipment. The unique straddle design allows you to wrap a wide variety of loads despite their contents or weight, giving you a safe-to-ship load every time.

Easy to Use

The machine’s simplistic design with single purpose knobs and switches makes it easy to set up wrap patterns. And the EZ Thread™ Film Delivery System ensures film is loaded correctly every time.

24/7 Support

Safety

Package Performance

Wrapping Safe-to-Ship Loads

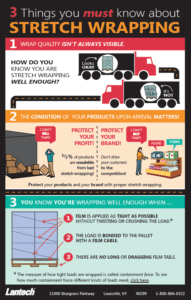

Stretch wrapping has become the standard way to unitize products for shipment. But, just because the load is wrapped and it’s shiny, doesn’t mean it’s ready for the back of a truck. Without proper stretch wrapping, loads can fail during shipment, causing damage to the product and damage to the brand. It is estimated that ineffective stretch wrapping is responsible for $60 billion of waste each year, just in consumer product goods. Now, more than ever, improving stretch wrapping processes, setting a standard and maintaining it is important in any shipping operation.

Three signs of a safe-to-ship load:

- There is enough containment force everywhere on the load.

- The load is locked to the pallet.

- There are no long or dragging film tails.

To learn more about effective stretch wrapping and other core packaging principals, visit our blog

Productivity Enhancements

Keep your driver on the forklift with the XT Cut and Clamp® and Click-n-Go™ Remote!

The XT Cut and Clamp® can help:

Reduce Labor Costs

- Labor required per load is reduced by an average of 2 minutes for most users.

- Typical customers save about $70,000 in 7 years.

Reduce Employee Injury

- Repetitive pulling and bending to attach or cut film can increase the risk of back injuries.

- Getting on and off the forklift multiple times can increase the likelihood of injury to the foot and ankle.

Increase Productivity

- Let the machine do the work so people don’t have to.

- Instead of standing next to the machine as it wraps, operations can perform other tasks like collecting another load or loading a truck.

Increase productivity by adding simple automation to your semi-automatic stretch wrapper.

The XT Cut and Clamp can save about two minutes of labor per load by keeping drivers on their forklifts. Two minutes may not sound like a lot, but for a company wrapping 80 loads a day and paying their employees $15 per hour, those two minutes account for about $10,000* annually (it only costs about $5,000 to add the XT Cut and Clamp to a semi-automatic stretch wrapper). Over a 7 year economic life of the machine, that is a savings of almost $70,000!

*80 loads/day x 2 minutes = 160 minutes/60 = 2.667 hours x $15 = $40 x 250 working days in a year = $10,000

Start the Stretch Wrapper Without Leaving the Forklift!

The Click-n-Go™ Remote control enables forklift drivers to simply place a pallet load on the

stretch wrapper, back away a few feet and start the machine.

Click-n-Go™ Remote meets the latest safety requirements outlined by the National Electrical Code. Using infrared technology and two-step activation process, the Click-n-Go is immune to

accidental activation from stray radio frequency.

Stretch Wrapping Resources

Semi-Automatic Stretch Wrapper Buying Guide

Don’t get it wrong! Straight talk about the key decisions around buying a semi-automatic stretch wrapper collected in one compact, easy to read guide. Learn about how to get the most value for your dollar, how to justify the cost, and how to avoid three classic buying mistakes.

XT Cut & Clamp® Simple Automation Calculator

How much time and money are you wasting without and XT? Our calculator estimates the amount of labor costs you can eliminate from your stretch wrapping processes when the machine can automatically attaching the film at the beginning of the cycle and cutting it at the end.

How to Improve Sustainability Efforts

Whether enforced by the government or internal goals are being set, companies of all sizes are looking for ways to become more sustainable. Here are 10 articles to help navigate the challenges of implementing sustainability initiatives in your packaging and shipping processes.

Questions On Which One Best Fits Your Needs?

Let us help you find the right equipment for your operations. Fill out the form to get in contact with our experts.

Are you looking for Parts, Service or Manuals? Click here.