Tray Erectors

Square Trays & No Jams

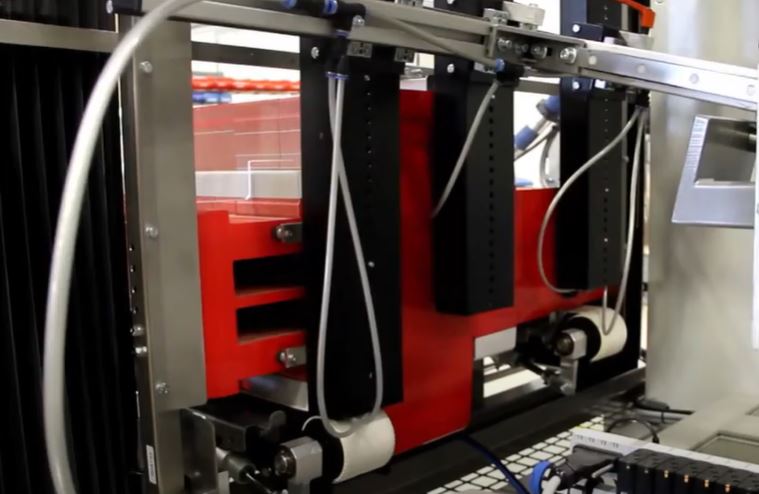

Lantech Tray Erectors are designed for a wide variety of tray styles and sizes. They feature an ergonomic and safe design, and produce perfectly square trays that maintain their visual appeal so your product looks great and is protected from damage.

Lantech packaging equipment is a notch above the rest. Our Lid Applicators and Lid Formers are easy to use, safe and reliable. See all of the advantages to choosing Lantech packaging equipment including video evidence.

Learn about Lantech’s Total Control System which allows every box, no matter the construction, to be erected with perfect 90-degree angles. The Total Control System makes it possible for every case to stack, pack and protect products better.

Why Choose Lantech Tray Erectors

Reliable

Don’t go down because of faulty equipment. Our unique design overcomes case variations and keeps jams at bay so your line can keep moving.

Easy to Use

The simplistic design makes the machine easy to use and changeovers quick. It will produce square cases every time.

24/7 Support

Our best-in-class warranty and availability of technical support will help get your machine back up and running fast.

Safety

From the ergonomic magazine loading, to safety curtains and shields, our machines were designed with safety in mind.

Package Performance

From the ergonomic magazine loading, to safety curtains and shields, our machines were designed with safety in mind.

Lantech Tray Erectors Produce Square Trays

Your packaging processes require different styles of lids in different flutes and wall thicknesses. Our precision Tray Former are designed to manage your trays throughout the entire process without losing control, with a square lidded tray as the end result.

- A mechanical driven pick-up frame ensures the transport from the magazine to the gripper position. Vacuum cups hold the blank firmly and keep it from shifting as they transfer to the horizontal blank position.

- We keep control over the blank during transport to the tray forming unit. Grippers center the blank before it is taken over to the suction cups. After taking over, the grippers keep the blank straight to avoid sagging of the blank.

- During transport to the forming unit, hot melt is applied to the tray blank. Exact positioning of the hot melt through an encoding system saves glue and avoids spilling of the glue.

- Encoder controlled tray blank transport ensures that the blank is always delivered exactly above the forming position. After the blank is stamped through the tray forming unit, the 4 sides of the lid are simultaneous pressed and glued, with which a perfect square lid is created.

How Lantech Tray Erectors can Contribute to Sustainability Efforts

Every day, companies are under increasing pressure to achieve sustainability goals and produce greater profit margins. Reducing materials at the packaging level can make a significant impact, especially if someone ships in high volumes. Many companies are also looking to their equipment to offer help in achieving their sustainability goals, and need equipment to be efficient, reliable and flexible.

On the materials side, many blanks are thrown out because of poor manufacturer construction or because they caused a jam in the machine. And cases with high recycled content can be challenging to erect. But what if your case erector could overcome these challenges? What if you could use every box in a bundle? You can with Lantech case equipment! Our Total Control System can take a destroyed blank and still erect it square while the unique pick-up frame can overcome the challenges that come with recycled corrugate.

Furthermore, efficiency and flexibility require machine adjustments be made quickly and easily – especially in environments that operate at fast speeds, have high production capacity, and that ship multiple products in a wide range of blank sizes. Lantech’s case erectors can accommodate a wide range of case sizes and are easily adjusted by anyone within approximately two minutes. Whereas equipment like the Multiformat Case Erector and Random Case Sealer can accommodate multiple box sizes without having to changeover.