With an estimated $60 billion of waste from unsalable products each year resulting from ineffective stretch wrapping in just the consumer products goods, food, and beverage industries, improving the effectiveness of stretch wrapping is an important step in any shipping operation.

The key to consistency is monitoring, measuring, and tacking

After determining the correct containment force for your pallet loads, it can be tempting to simply set up the stretch wrapper and wrap loads. This, however, doesn’t mean your job is done. To ensure pallet loads are consistently wrapped effectively, you’ve got to monitor, measure, and track.

These are key tasks that help you identify how well your stretch wrapping is working and it can also help you identify problem areas or opportunities for improvement.

Some of the metrics we recommend monitoring, measuring, and tracking include:

Some of the metrics we recommend monitoring, measuring, and tracking include:

- Containment force

- Costs

- Damage

Containment Force

It’s especially important to measure and monitor this fundamental stretch wrapping performance measure. Unless you have stretch wrappers that automatically monitor containment force, check it at least once per shift for each wrapper. Correct any variations from your standard immediately.

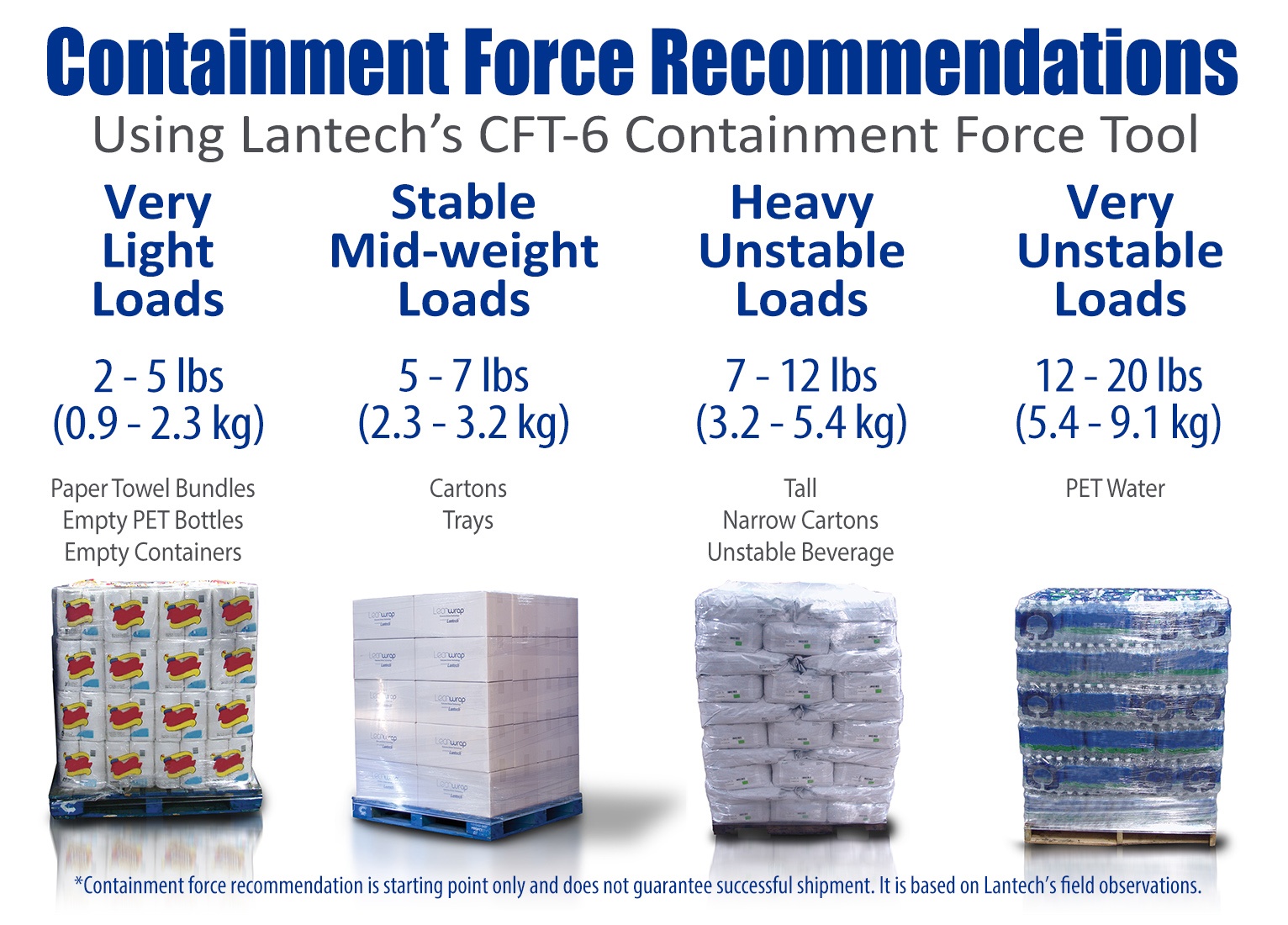

Not sure what your containment force should be? We have a simple tool based on years of recorded field observations. Our Containment Force Recommendations is a good reference for users who need guidelines or want another source to check their current containment force standards against.

Costs and Damage

Monitoring and tracking costs and damage provide useful data for evaluating the ROI of your stretch wrapping efforts. Ideally, this begins before you implement new practices or change your stretch wrapping practices, creating baselines so you have clear “before” pictures to compare to.

Measuring and comparing will give you a concrete understanding of how efficient your stretch wrapping efforts are. When tracked consistently, any spikes in costs or damage will also serve as the canary in the coal mine, letting you know if there’s a problem in your pallet wrapping process.

- This post was published on November 7, 2016 and updated on September 13, 2017.

November 7, 2016