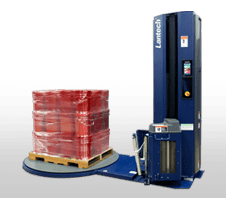

QL Semi-Automatic

Our Most Popular Semi-Automatic Stretch Wrapper Enhanced with Load Guardian

QL400

The latest addition to Lantech’s L-Series, the QL produces safe-to-ship loads quickly and easily for any load configuration.

What's New

Ready to Wrap Profiles

QL400XT

The latest addition to Lantech’s L-Series, the QL produces safe-to-ship loads quickly and easily for any load configuration.

What is Load Guardian?

Load Guardian is Lantech’s patented control system that creates, maintains and delivers the right amount of containment force for safe-to-ship loads every time. Load Guardian minimizes operator interactions and eliminates the guess work for stretch wrapping any load configuration

If you...

- Wrap the same load different ways?

- Ship across town, cross-country or over-seas?

- Have more than one operator. do they all have their own ways of doing things?

- Have crazy shaped loads?

- Wrap to customer specifications?

- Wrap inbound and outbound loads differently?

Load Guardian will ensure every load is wrapped correctly.

Load Guardian

Creates, Maintains and Delivers Safe-to-Ship Loads

Creates

Load Guardian creates and

saves profiles.

- Intuitively guides users through the profile creation process, using recognizable icons and smartphone-like simplicity, to calculate the right containment force.

- Eliminates the consequences that can occur when an operator has to make 12 or more decisions to stretch wrap a load.

Maintains

Load Guardian maintains profile standards automatically.

- Eliminates or minimizes routine operator touches and tweaks with single tap profile selection.

- Eliminates the consequences that can occur when an operator has to make 12 or more decisions to stretch wrap a load.

Delivers

Load Guardian delivers the right amount of containment force.

- Provides a knowable, repeatable cost per load.

- Eliminates the consequences that can occur when an operator has to make 12 or more decisions to stretch wrap a load.

NEW Load Guardian Features

Ready to Wrap Profiles

Operators simply match one of the Ready to Wrap Profiles to their load and start wrapping, eliminating the guess work for stretch wrapping almost any load.

Additional New Features

- Expanded capabilities for short loads, reverse rotation, alternative wrap heights, and dual turntable auto alternating loading.

- Ability to start the machine with a quick pull of the lanyard.

Load Guardian Advantages

The QL comes with all the standard Q Semi advantages, as well as these unique features.

- Intuitively guides users through the profile creation process to calculate the right containment force.

- Eliminates the consequences that can occur when an operator has to make 12 or more decisions to stretch wrap a load.

- Eliminates the need for operators to make machine adjustments for common load applications through pre-established, yet customizable wrap profile settings.

- Facilitates safer and easier interactions.

- Generates knowable and repeatable wrapping costs.

- Stack & Band, Stack & Wrap and Labels Apps.

- Provides simple video and text instructions for countering stretch wrapping problems, such as film breaks, product crushing or load twisting.

- Reduces downtime.

- Built in lessons and manuals.

- Customized operator access.

- Determine who can create profiles, select, edit and/or adjust settings.

- Create user profiles and passwords with the new User Access feature.

- Advanced diagnostics, productivity charts and fault tracking.

- Load Guardian is available in features English, Polish, French, German, Danish, Dutch, Spanish, Portuguese, Turkish and Russian.

Video Gallery

The Lantech QL400

Load Guardian and

Ready to Wrap Profiles

Multi-Profile Lanyard

Click-n-Go Remote

Profile Creation and Selection

Load Guardian & XT Cut & Clamp

Gravity Turntable

How to Change the Wrap Pattern

Lantech Semi-Automatic Stretch Wrapper Exclusives

Click on each to learn more.

Eliminate double handling and add to your quality control processes.

Pallet Grip®

Avoid product damage by locking the load to the pallet.

Keep loads from sliding off their pallet with a film cable!

Sudden stops, starts or constant vibrations can cause loads to slide off their pallets unless you do something about it. Lock your load to the pallet with Pallet Grip®.

Pallet Grip®:

- Rolls the bottom film web into a tight cable.

- Drives the cable down just below the top boards of a pallet.

- Avoids punctures to film caused by forks.

20 million loads slide off their pallet each year, resulting in $6 billion in damaged products.

Millions of loads slide off their pallets during shipment each year causing billions of dollars of rework and waste. If your load isn’t properly bonded or “locked” to the pallet, it can slide off and be damaged during shipment.

Stretch wrapping all the way down to the bottom of the pallet isn’t enough. Puncture holes in the film – caused by the forks of a forklift or pallet jack – may spread up the load and jeopardize the integrity of the wrap, leading to shipping damage.

Pallet Grip® is compatible with all pallet types.

Why take unnecessary risk? Lock your load to the pallet.

Roll Up

Pallet Grip rolls the bottom 3-6 inches of film webs into a tight cable during the last seconds of the wrap cycle.

Drive Down

The cable is placed (driven down) just below the top boards of the pallet, low enough to lock the load, yet high enough to avoid forks.

Avoid Punctures

If wrapped to the bottom of the load, forks of a forklift or pallet jack will puncture the film, jeopardizing the integrity of the wrap and can propagate up the load.

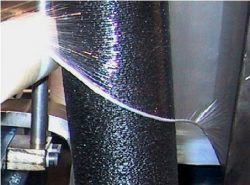

XT Cut and Clamp®

Improve productivity by saving 2 minutes of labor per load.

Keep your driver on the forklift with the XT Cut and Clamp®!

The XT Cut and Clamp® cuts the film at the end of the wrap cycle. The XT then holds the film and attaches it to the next load. When using the XT, your drivers can stay on their forklift as the load is wrapped, giving them the opportunity to do something more productive and return to a load that is ready to be picked up.

The XTCut and Clamp® can help:

- Reduce labor costs.

- Reduce potential employee injury.

- Increase productivity.

Increase productivity by adding simple automation to your semi-automatic stretch wrapper.

Operators who are using forklifts to transport loads to and from the stretch wrapper must dismount to start the wrap cycle, then remount the forklift to take the wrapped load away. If following all necessary safety measures, this 21 step process can take up to two minutes. What’s worse is that most operators stand next to the machine, doing nothing, as the load is being wrapped – adding another two minutes of unproductive time.

The XT Cut and Clamp can save about two minutes of labor per load by keeping drivers on their forklifts. Two minutes may not sound like a lot, but for a company wrapping 80 loads a day and paying their employees $15 per hour, those two minutes account for about $10,000* annually (it only costs about $5,000 to add the XT Cut and Clamp to a semi-automatic stretch wrapper). Over a 7 year economic life of the machine, that is a savings of almost $70,000!

*80 loads/day x 2 minutes = 160 minutes/60 = 2.667 hours x $15 = $40 x 250 working days in a year = $10,000

Superior Design of the XT Cut and Clamp®

- Completely mechanical – requires no air or electricity.

- Steel frame protects internal components from damage.

- Internal components only come out of the steel frame when activated.

- Mounted on the side of the turntable for greater visibility.

- Easy to clean.

Benefits of the XT Cut and Clamp®

Reduce Labor Costs

- Labor required per load is reduced by an average of 2 minutes for most users.

- Typical customers save about $70,000 in 7 years.

Reduce Employee Injury

- Repetitive pulling and bending to attach or cut film can increase the risk of back injuries.

- Getting on and off the forklift multiple times can increase the likelihood of injury to the foot and ankle.

Increase Productivity

- Let the machine do the work so people don’t have to.

- Instead of standing next to the machine as it wraps, operators can perform other tasks like collecting another load or loading a truck.

EZ Weigh Integrated Scale™

Eliminate double handling and add to your quality control processes.

Wrap and weigh in one easy step!

The EZ Weigh™ Integrated Scale is a smart addition to your stretch wrapper. Without adding any additional work to your stretch wrapping and shipping process, the EZ Weigh™ Integrated Scale can help you:

- Eliminate expensive freight fines.

- Stop wasting expensive labor.

- Protect your reputation.

Check every load for quality and freight costs.

The first thing to understand is the consequences of not weighing your loads.

- Less-than-truckload (LTL) carriers charge expensive re-weigh fines. To avoid these fines, you might overestimate the weight of your loads and overpay for freight.

- Without a final quality check, you could be sending incomplete loads to your customers, thereby damaging your relationship.

- If you are currently weighing your loads on a platform scale, you are wasting 30 seconds to 1.5 minutes of expensive labor when moving a load from the stretch wrapper to a scale.

The EZ Weigh™ is your opportunity to save money, protect your brand and increase productivity. Because the scale is built into the stretch wrapper, it requires no additional time, work or space to weigh loads.

Superior Design of the EZ Weigh™ Integrated Scale

- The low-profile design uses the same footprint as the standard Q Semi.

- The scale is calibrated at our factory before shipment.

- New technology allows operators to use a smartphone app to send and receive scale data via a wireless module to and from the scale indicator.

- Sloped skirt protects load cells from being damaged by the forks of a forklift or pallet jack.

Everyday Problems the EZ Weigh™ Helps You Solve.

Eliminate Freight Fines

- Less-than-truck load companies collect $1 billion annually in re-weigh fines.

- Only pay what you owe.

- Accurate weight from scale helps calculate correct freight costs.

- Avoid overestimating or underestimating weight.

Stop Wasting Expensive Labor

- The EZ Weigh™ wraps and weighs your load at the same time.

- Save between 30 seconds and 1.5 minutes from not double handling loads.

- If you’re double handling loads from a stretch wrapper to a platform scale, you may be losing $6,500 over the course of five years.

Protect Your Reputation

- Weigh loads as the final step in your quality control process.

- Verify the pick list weight against the weight measured from the scale.

- Use records of weight to verify product arrived intact without pilferage.

- Flag any variations from load to load.

Click-n-Go Remote™

Stretch Wrapping Loads at the Touch of a Button!

The Click-n-Go™ remote control enables forklift drivers to simply place a pallet load on the stretch wrapper, back away a few feet and start the machine.

Click-n-Go remote meets the latest safety requirements outlined by the National Electrical Code. Using infrared technology and two-step activation process, the Click-n-Go is immune to accidental activation from stray radio frequency.

It’s available as an option on the QL400XT, Q300XT, Q300XT Plus, and S300XT Simple Automation™ stretch wrappers.

Additional Resources

Our chart gives you a sense of how much money your business may be losing to LTL carriers. To find the approximate dollar amount, refer to the number of loads per day and the average wage you pay operators.

Straight talk about the key decisions around buying a semi-automatic stretch wrapper collected in one compact, easy to read, guide. Make good decisions, get the right wrapper.

How much time and money are you wasting? Our calculator estimates the amount of labor cost you can eliminate from your stretch wrapping process with the XT Cut and Clamp®.