Make sure your loads arrive at your customers’ locations in “as made” condition. Don’t chance it. Here are three things you can do regardless of the model or age of your stretch wrapper to improve your probability of success.

1. Use the right amount of containment force

1. Use the right amount of containment force

Make sure you’re applying the right amount of containment force everywhere on the load. It’s just as important to make sure you’re getting it, however. Proper containment force can mean the difference between a load that’s safe-to-ship and a disaster. If you don’t know what your containment force should be then you should wrap your load as tight as possible. Just be sure to not crush your products.

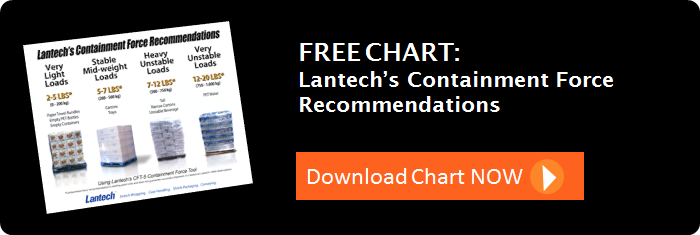

While containment force is best determined through experience, we have produced a tool called Containment Force Recommendations. It’s a simple tool that users may refer to as a general guide based upon many years of our recorded field observations. It’s a great place to start if you’re not sure what your containment force should be.

2. Keep maintenance up-to-date

When your stretch wrap machine isn’t working right you can end up with film breaks. These film breaks don’t just slow down your operation; they can put your loads at risk.

When film breaks happen, the operator’s goal is to quickly stabilize the system and make the breaks stopping happening. The quick fix is to turn down the film tension. Unfortunately this will also reduce the containment force on the load and increase the risk for bad things to happen. This process is what we call the Circle of Doom.

To learn more about the Circle of Doom, read our blog post Three Things to Check When Your Stretch Film Breaks.

Film breaks are just one symptom of not up-to-date maintenance. Other causes are unplanned downtime, excessive machine wear, degraded pre-stretch, inconsistent film tension and poor film wipe-down.

3. Keep loads inside the pallet

Don’t violate the invisible walls of the pallet. Your products should never overhang the pallet and should only be slightly inboard. Products that overhang the pallet are at a high risk for being damaged. Keep the load inside the pallet and keep it plumb.

You may be interested in these related posts:

This post was published on October 4, 2016 and updated on November 1, 2018.

October 4, 2016