The simple answer is that quality machine stretch film typically stretches 3x or more.

The right answer is….it depends on the stretch film, the machine and most importantly, your product, loads and goals.

Here’s the full answer

Confusing stretch with tight & secure

Sometimes you’ll hear people refer to the plastic that they wrap around pallets as shrink film. You know what they mean of course, but the proper name is stretch film for a reason.

Modern stretch film formulations are made to stretch – but maybe not for the reason, or to the extent that you imagine.

When Pat Lancaster invented the first stretch wrapper in 1972 he used a 60” roll of plastic film designed for use in dry cleaning facilities. The idea was to lay the film against the rotating pallet and rely on a core brake to slow the film enough that it stretch a bit and compressed the load as a result. That invention rapidly evolved to the spiral wrap so popular today. The polyethylene stretch film we rely on now rapidly followed.

When Pat Lancaster invented the first stretch wrapper in 1972 he used a 60” roll of plastic film designed for use in dry cleaning facilities. The idea was to lay the film against the rotating pallet and rely on a core brake to slow the film enough that it stretch a bit and compressed the load as a result. That invention rapidly evolved to the spiral wrap so popular today. The polyethylene stretch film we rely on now rapidly followed.

That’s essentially the same process repeated thousands of times each day as workers hand wrap loads with 12 & 18″ wide rolls of hand stretch film.

And most importantly, load security is determined by containment force – or wrap force X film layers. It turns out that stretching isn’t a factor.

Dollars & cents

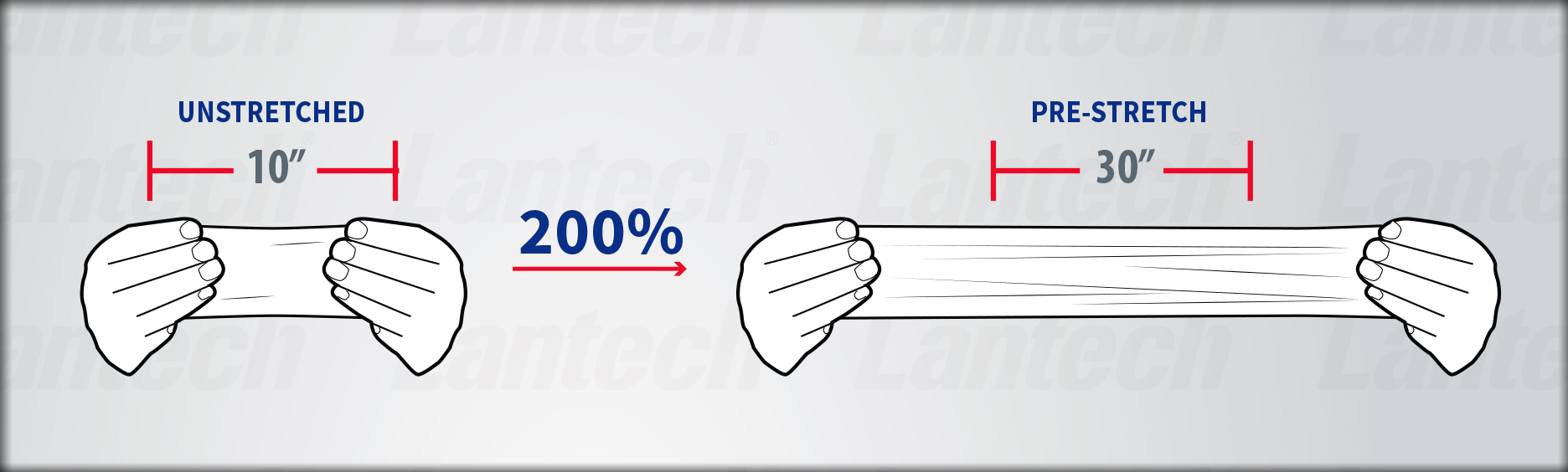

Stretching the film (or, more precisely, pre-stretching the film before it leaves the film delivery system) is an economy measure. Pre-stretching film is what made stretch wrapping affordable and opened up the stretch wrapping and stretch film industries that we know today.

Pre-stretching film saves money.

Common pre-stretch percentages (which are typically determined by a set of gears in a wrappers pre-stretch carriage) range from 150-300%. That means that every linear foot of film coming off a roll represents 2.5 to 4 feet of film on the load.

That’s some pretty compelling savings! In fact, most companies buy their first pallet wrapper with a simple film savings calculation.

More is better, right?

To a point. There are more factors to consider here.

Film attributes include:

- gauge

- formulation

- puncture & tear resistance

- roll length

- price/lb

Load attributes include:

- weight

- load configuration (like a cube or uneven)

- need to lock load to pallet

- inboard or outboard (product is smaller or larger than the pallet respectively)

- containment force which is a product of wrap force (tension) and revolutions

Best practices for determining the optimal film usage include:

- Establish standards for the load: containment force value, load-to-pallet bond, no long or dragging film tails. They maximize the probability of safe shipment.

- Determine settings: These are the film choices (quality, gauge and price) and machine adjustments (pre-stretch percentage, wrap force, top and bottom wrap counts, film delivery system speed up and down, film overlap, etc.) that ensure the standards are achieved.

- Establish a feedback loop that ensures the standards are maintained,

The reality is that thinner film doesn’t always result in a net film savings! Decreases in film thickness result in a loss of wrap force because of increased film breaks. Because it’s notoriously hard and time consuming to find the root causes of film breaks, operators frequently get rid of them simply by decreasing the wrap force until they stop. Consequently, more film layers must be applied to recover and maintain containment force that’s lost and film consumption increases.

Every load does not have an optimal wrap pattern. It does, however, have an optimal containment force. If my load needs 10 pounds of containment force, I can get it by using a thin film and applying lots of layers or I can use a thick film and apply fewer layers – the resulting containment force can be the same but the wrap patterns and throughput rates can differ significantly.

Film spec is not the load spec

Most machine films are engineered today to comfortable pre-stretch to 300%. If you stretch further you may experience more breaks – particularly on corners of loads where tension increases with most film delivery systems.

Technology will let you stretch your budget figuratively and literally. The risk is that savings achieved through down gauging and extreme pre-stretch may be lost to the damaged product which can result when containment force is adversely impacted by related film changes.

The real question companies need to answer is “What containment force is required to safely ship my load?” From there, local experts familiar with films and machines can design the right combination and establish parameters to ensure loads are properly wrapped.

The short answer to how much does stretch wrap stretch? Stretch film will stretch as much as your machine is designed to stretch it. 300% is not unusual – but may not be the best answer. Stretching the film budget in one direction, without considering other impacts, can cost far more in product damage than is saved on film. Remember, there is balance between thick stretch films applied with high wrap force and few film layers versus thin films applied with low wrap force and more film layers.

Wondering how much pre-stretching your stretch film could save you?

Good question. It’s one of the classic justifications for a new stretch wrapper. We’ve got a free calculator available for download that you can use to estimate savings. Grab your copy here.

And don’t forget other considerations. In high speed wrapping applications, overstretching film can lead to frustrating and costly down-time through film breaks. This is especially common on irregular loads (like distribution centers) and corners of loads if the machine doesn’t adjust the way it feeds film.

Click here to see the Film Cost Savings Calculator.

You may be interested in these related posts:

This post was published on June 28, 2016 and updated on November 9, 2018.

June 28, 2016