The Power of LeanWrap® Technology

The best-in-class solution for real-world packaging environments

For over 50 years, Lantech has been at the forefront of stretch wrapping innovation. Based on that relentless commitment to innovation, our LeanWrap Automatic Stretch Wrappers provides the best-in-class solution for real-world packaging environments.

LeanWrap Technology is not a single feature — it is an integrated system designed to work together to prevent film breaks, optimize film usage, and deliver loads that arrive in ‘as-made’ condition, at the lowest cost and lowest carbon footprint. This means your customers can count on less downtime, safer loads, and lower operating costs.

Watch as Lantech’s R & D Director, Michael Mitchell, explains.

Lantech's LeanWrap Innovations

The Next Generation of Metered Film Delivery®

Reduce Film Consumption

One of the biggest causes of downtime in stretch wrapping is film breaks — and traditional film delivery systems can make this worse by reacting to tears and film imperfections with more force, which can propagate into a full film break.

Lantech’s patented Metered Film Delivery has always worked differently by measuring the perimeter of the load and only paying out the length of film needed to give a predetermined amount of wrap force.

The next generation of Metered Film Delivery builds upon the current performance with precision control for all load sizes while maintaining consistent containment force per revolution, resulting in even fewer film breaks and lowering film consumption. By providing more balanced containment force on the long and short sides of a load, it can better handle off-center loads and more extreme load shapes.

Here are just some of the ways the next generation of Metered Film Delivery can help your customers achieve the lowest carbon footprint in their stretch wrapping process:

- Eliminates film breaks caused by film imperfections – Less downtime!

- Higher containment force per revolution reduces film usage – Wrap tighter with less film!

- No twisting or crushing the load – Less damage!

Learn how one food and beverage company reduced their film consumption by 25% with Metered Film Delivery!

Load Seeking Clamp® 4.0

Eliminate Film Breaks

Film breaks at the start of a wrap cycle can bring production to a halt, and are usually caused by film clamp failure. Film pulls or slips out of the clamp, the acceleration of the film delivery system can snap film, or vacuum suction issues can arise.

The Load Seeking Clamp 4.0 addresses this by firmly securing the film with a pneumatic bladder with 3X the holding force of traditional clamps.

Additionally, the clamp travels to the side of the load with the leading film tail in tow. This ensures that the film is fully captured within the wrapped load and reduces the risk of tearing as it passes over the clamp. It also eliminates film tenting that leaves corners exposed, which maintains containment force at the base of the load.

LSC 4.0 is a small innovation that delivers massive results for productivity and load security:

- Virtually eliminates film breaks at the start

- Increases containment force at the load’s base

- Reduces downtime and operator intervention

Pallet Grip®

Stop Load Shifting

Why do companies stretch wrap their loads? To get their products from their facility to its destination, damage free, and, ideally, at the lowest cost, too!

Damage during transit costs companies a lot of money…but it also damages their brand and reputation when a load arrives to an end user in pieces.

Pallet Grip dramatically reduces transport damage by rolling the bottom 6 inches of the film web into a tight cable, and places it above the top board of the pallet. This placement locks the load to the pallet and keeps it out of the way of fork truck forks. Locking the load to the pallet with Pallet Grip prevents loads from shifting during transport and ensures your customers’ products arrive at their destination in as-made condition.

Watch how powerful Pallet Grip is!

Pallet Grip helps you wrap loads at the lowest cost by:

- Preventing shifting during transport — reducing damage and returns

- Keeping film out of forklift range – film won’t get caught by the forks and tear, risking damage later

- Improving shipment quality and reducing total cost of ownership

Load Guardian®

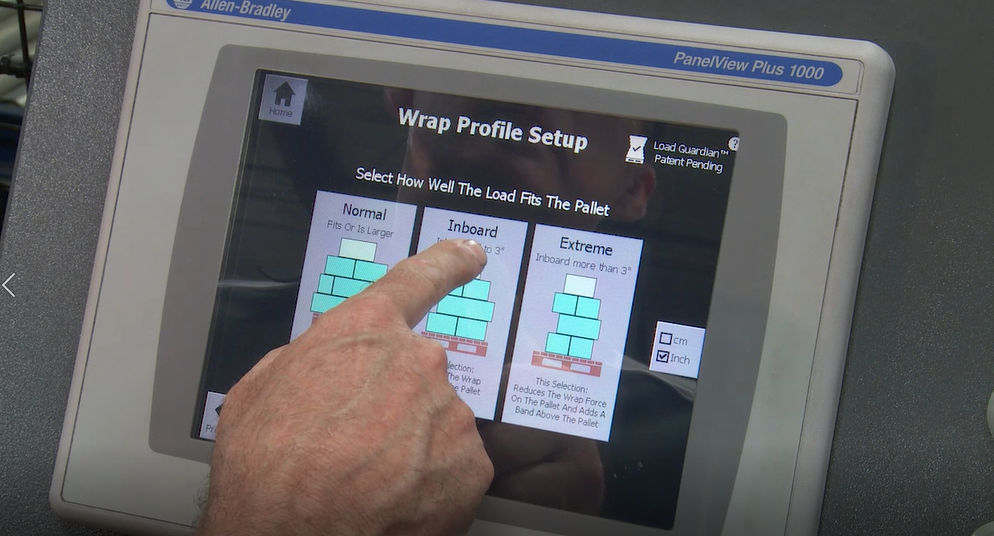

Remove Operator Guesswork

One of the most challenging parts of operating a stretch wrapper is configuring machine settings for different loads. Mistakes can lead to wasted film, unstable loads, and costly product damage.

Load Guardian does not ask the operator for machine settings. It asks the operator a few questions about the load being wrapped – which are obvious by just looking at the load – and then asks the gauge of film being used. From there, Load Guardian automatically produces a wrap profile that delivers the right amount of containment force, evenly across the load.

Additionally, Load Guardian maintains containment force even if the wrap force must be turned down for sub-quality film or particularly hostile loads. This patented system removes the need for specialized training and the guesswork to wrap loads effectively, and at the lowest cost.

Key benefits of Load Guardian:

- Ensures safe-to-ship loads every time

- Minimizes film waste and improves consistency

- Easy to use — no special training needed

Data Deep Dive: ARC – Automatic Roll Change Option

Some customers, like beverage bottlers, need the highest levels of uptime with the fewest amount of operator interactions. For those situations the answer is Lantech’s Automatic Roll Change option (ARC)…and we have the data to prove it.

Film breaks and film exhaustion are major causes of production downtime, but ARC eliminates these by allowing machines to hold and replenish up to three additional rolls of film. It also provides a separate access gate that allows for film loading WHILE THE MACHINE IS RUNNING!

We’ve collected 3 years of data from a large bottling facility using two machines wrapping the same loads – an SL Automatic and an SL Automatic with ARC. Compared against the SL Automatic, the data showed that the SL Automatic with ARC:

- Eliminated 186 hours of downtime per year

- Eliminated 1,921 unscheduled operator touches per year

- Reduced the number of line-stopping events by 82%

Over that 3 year period, the average uptime of the SL Automatic with ARC was 99.4%! Wow!

Download our ARC SmartLit to share with your team!

Leveraging LINC® for Optimized Automation

In today’s competitive supply chain landscape, your customers are constantly seeking ways to enhance operational efficiency, reduce costs, and maintain high product quality. This is especially true in the warehouse and production environments, where the performance of stretch wrappers can directly impact productivity and throughput.

Lantech’s LINC (Lantech Intelligent Network Connection) is an advanced IoT machine visibility solution designed specifically to provide your customers with the ability to monitor real-time data, optimize performance, and predict maintenance needs. With LINC, your customers can significantly improve system uptime, productivity, quality, and cost efficiency.

LINC provides the following customer benefits:

- Reduced downtime

- Improved packaging consistency and quality

- Operational efficiency and throughput optimization

- Cost reduction

- Scalability across multiple locations

Download a NEW white paper that explains the key features and benefits of LINC called “Leveraging LINC for Warehouse Automation.”

This revolutionary remote machine support option is now available on all Automatic Stretch Wrappers (excluding LanRinger) and modular case and tray handling equipment.

Learn more about LeanWrap with these resources

Stop the Bleeding In the Single-Use PET Industry’s Supply Chain

Learn the signs of an effectively wrapped load and how you can achieve a safe-to-ship load at the lowest cost by downloading this guide.

Learn MoreFrom the CEO’s Desk: The Value of a Lantech LeanWrap® Stretch Wrapper

A Message From Jim Lancaster, Owner & CEO, Lantech Sometimes the technical […]

Learn More