FOR IMMEDIATE RELEASE

LOUISVILLE, KY – February 2, 2026 — Lantech, the global leader in stretch wrapping technology, today announced the launch of AMR-integrated stretch wrapping solutions, led by the new SL400LT with AMR integration. While AMR compatibility is not required—or practical—for every stretch wrapping application, Lantech now offers AMR integration capabilities for select stretch wrappers designed to operate in automated warehouse environments. Alongside this milestone, Lantech also formally launched two new stretch wrappers—the SL400 and SL400LT—both now available for sale.

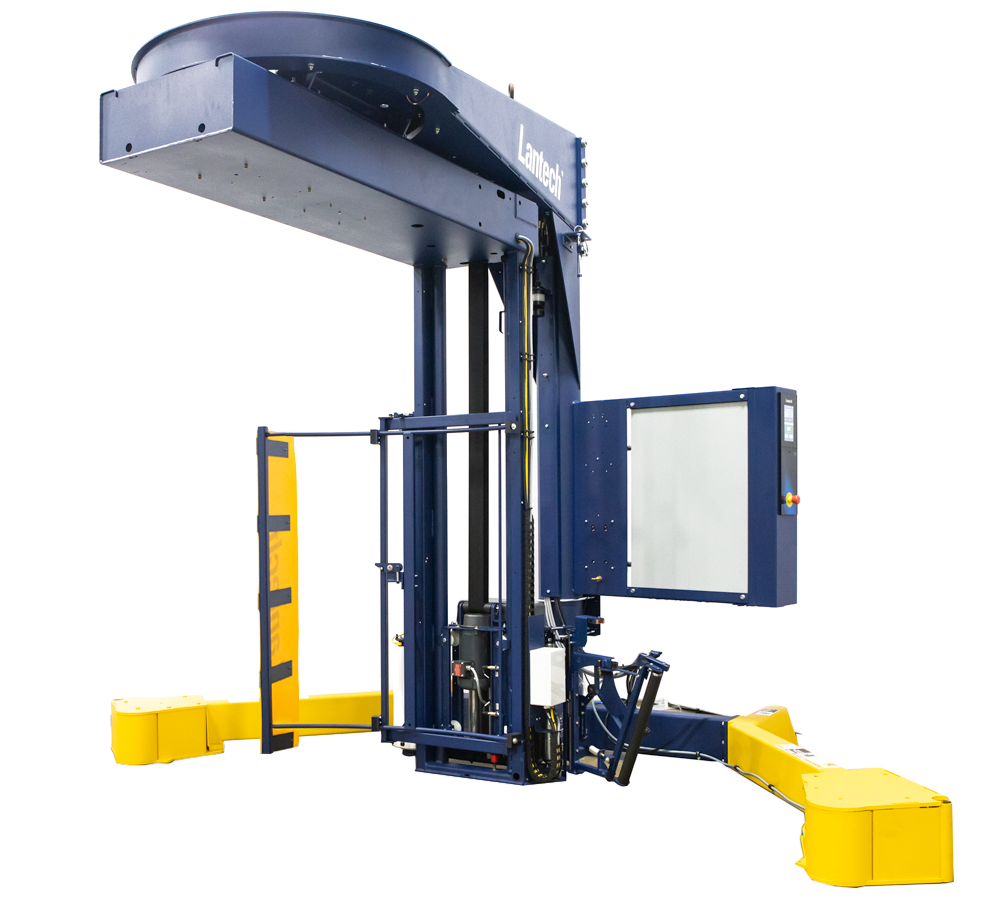

The SL400 is Lantech’s simple automation solution for warehouse environments

Lantech initially previewed its AMR integration direction in late 2025. Today’s announcement represents the formal commercialization of that vision, with clearly defined product offerings, expanded technical detail, and commercial availability for customers and system partners.

“Automation strategies look different from one operation to the next,” said Jim Lancaster, CEO of Lantech. “The SL400 and SL400LT bring proven load-containment technology into semi-automatic machines in a way that fits how operations actually run today. With technologies like Load Guardian® and TurboTak® plus AMR integration options, we’re giving customers practical solutions to address labor challenges, maintain uptime, and move forward with automation confidently.”

Stretch Wrapping Built for Automated Environments

Highly automated warehouses depend on AMRs to move product efficiently with minimal human intervention. In these environments, uptime and safety are critical, and disruptions such as film breaks or loose film tails can quickly bring operations to a stop and require manual recovery.

Lantech’s AMR-integrated stretch wrapping solutions are designed to operate seamlessly with AMRs, supporting automated pallet flow without requiring fundamental changes to existing infrastructure. Rather than offering a one-size-fits-all approach, Lantech works collaboratively with customers and system partners to determine where AMR integration makes sense and how best to implement it based on specific operational requirements and equipment needs.

Introducing the SL400 and SL400LT

The newly launched SL400 and SL400LT stretch wrappers are designed to automate stretch wrapping in facilities with varying levels of automation—without the need for conveyors, ramps, or weight restrictions.

- The SL400 is ideal for warehouses transitioning from manual processes. Loads are placed directly on the floor, and the wrap arm travels around the load, making it well suited for very light, very heavy, unstable, or order-picked loads. Technologies such as Load Guardian with Ready-to-Wrap profiles reduce operator guesswork and help ensure safe-to-ship loads at the lowest possible cost.

- The SL400LT is designed for manufacturing and highly automated environments where minimizing operator involvement and maximizing uptime are critical. In addition to Load Guardian, the SL400LT incorporates technologies like Load Seeking Clamp and TurboTak that directly address the most common causes of downtime in automated operations.

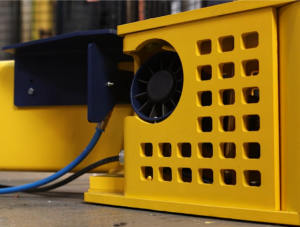

TurboTak eliminates dragging film tails by providing two stages of precise, high-velocity blasts of air.

TurboTak Technology: Eliminating Dragging Film Tails

A key innovation included with the SL400LT is TurboTak, one of Lantech’s technologies developed to support automation-intensive environments. Loose and dragging film tails can get caught up in conveyors, shut down robots and retrieval systems, and accidentally flag false warning signs in other automated equipment.

TurboTak eliminates dragging film tails by providing two stages of precise, high-velocity blasts of air. The first blast shapes the film web in the precise location; the second, more focused blast, “nails” the film tail to the underlying layers of film so it will not interfere with surrounding equipment or AMRs. The system requires no heat and is fully self-contained, with no exposed or moving parts, making it robust enough for demanding industrial environments.

By eliminating loose film tails—a common source of disruption in automated facilities—TurboTak helps reduce manual intervention, protect uptime, and maintain load integrity throughout the warehouse.

Designed for the Operation You Have Today

Both the SL400 and SL400LT are designed to integrate into existing operations, allowing facilities to advance automation at their own pace. With no conveyors or ramps required and no load weight restrictions, these solutions provide flexibility for operations ranging from manual warehouses to highly automated facilities. Where AMR integration is required, Lantech offers the expertise to support seamless implementation on appropriate stretch wrapping solutions.

Availability

The SL400 and SL400LT are available for order in North and South America beginning February 2, 2026.

More information can be found at www.lantech.com, or contact Lantech to discuss AMR integration opportunities at www.lantech.com/quote.

Download related photos here.

###

About Lantech

In 1972 Lantech made an impact on the world by inventing the stretch wrapper and changing the way companies package and protect their products for shipment. Now, billions of pallet loads are stretch wrapped every year. Today we build a full line of case and tray handling, stretch wrapping, and pallet conveying equipment, with manufacturing facilities in the United States and the Netherlands, and sales and technical support worldwide. Over the years our business has been built on innovation, customer support and the mission to dramatically reduce shipping damage globally.