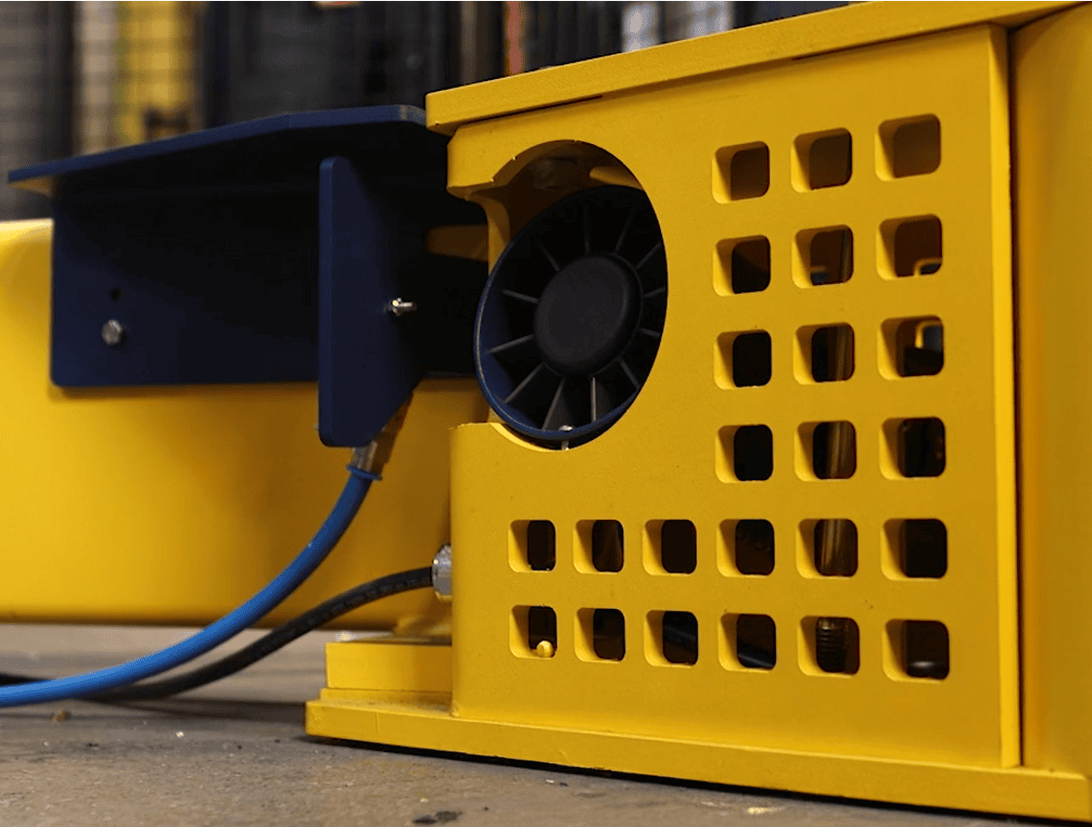

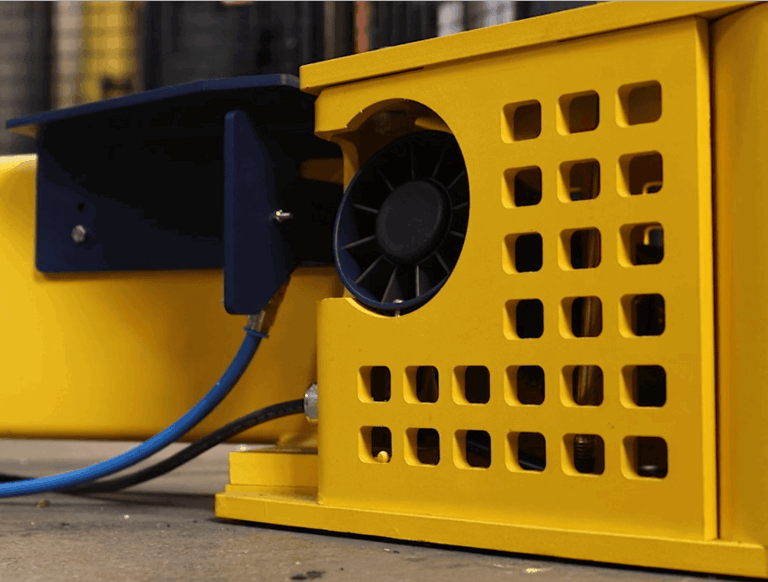

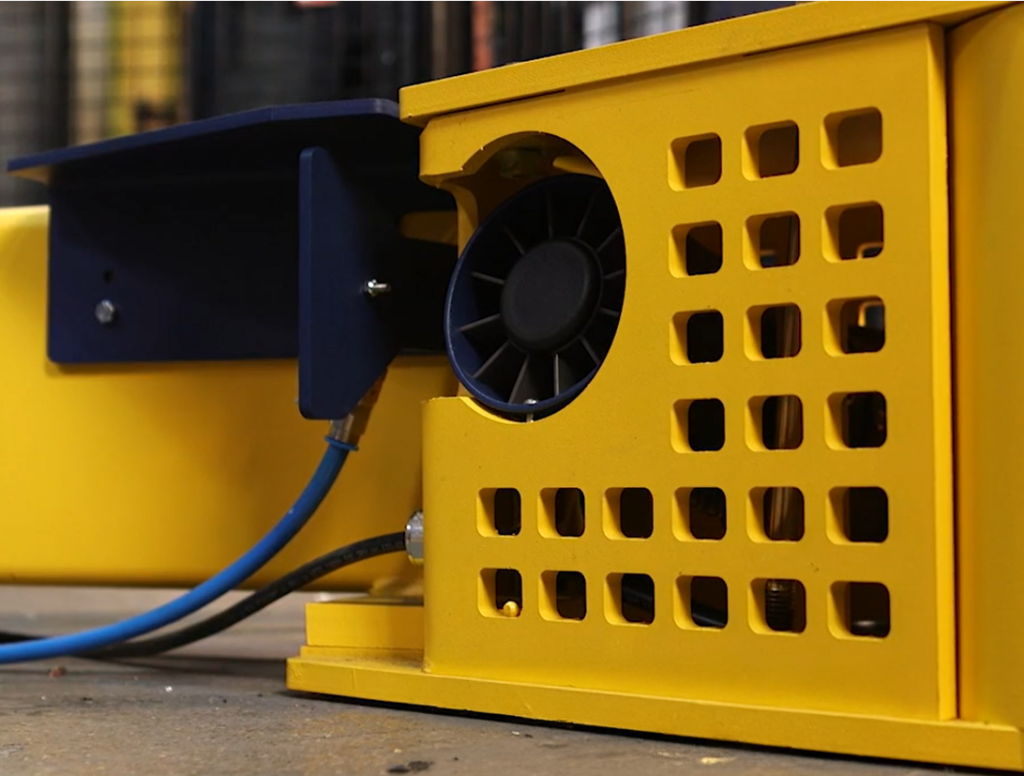

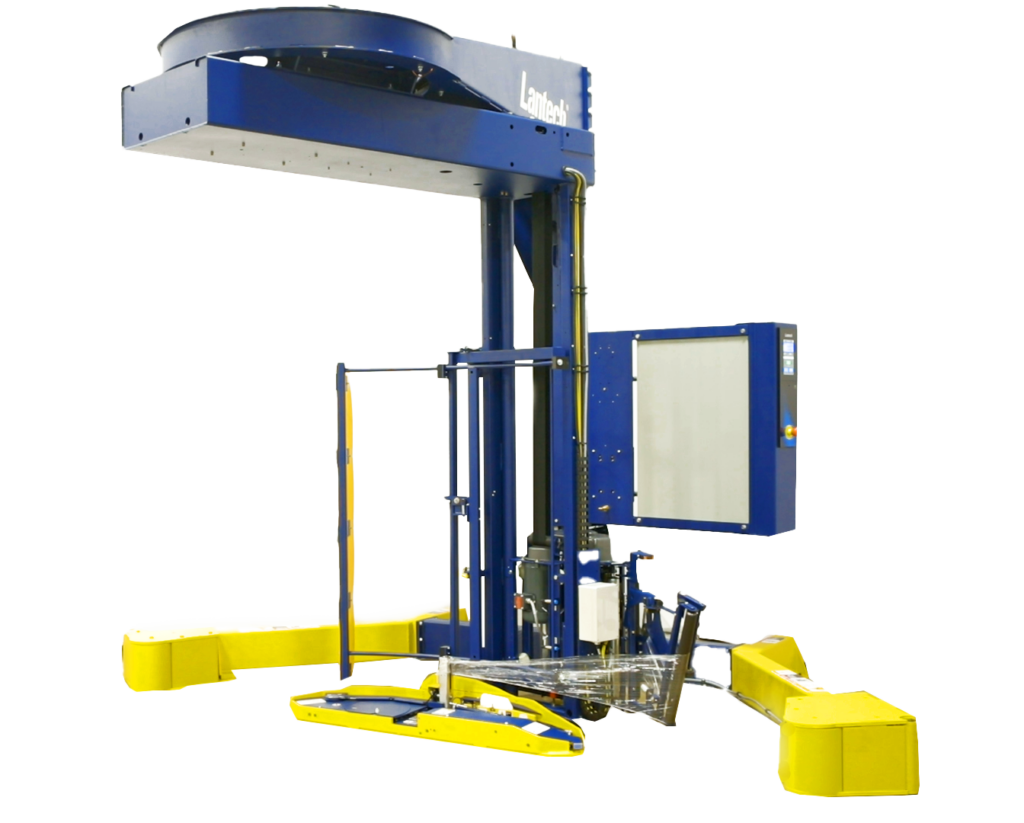

Lantech SL400LT Stretch Wrappers

Lantech’s simple automation solution for manufacturing environments

- Ideal for very light, very heavy or very unstable loads

- Little-to-no operator touches

- Virtually no downtime

- Saves 2 minutes of forktruck labor per load

- Eliminates film breaks and film tails

Ideal for manufacturing environments

Specifications

Performance

Peak Production Speed

Up to 40 Loads/Hr

Load Size Diagonal (Recommended)

1931 mm (76")

Maximum Load Wrap Height

2032 mm (80")

Maximum Load Weight

Floor capacity

Performance Features

XT Cut and Clamp 5.0®

Not available

Auto Film Cut-Off®

Optional

Pallet Grip®

Standard

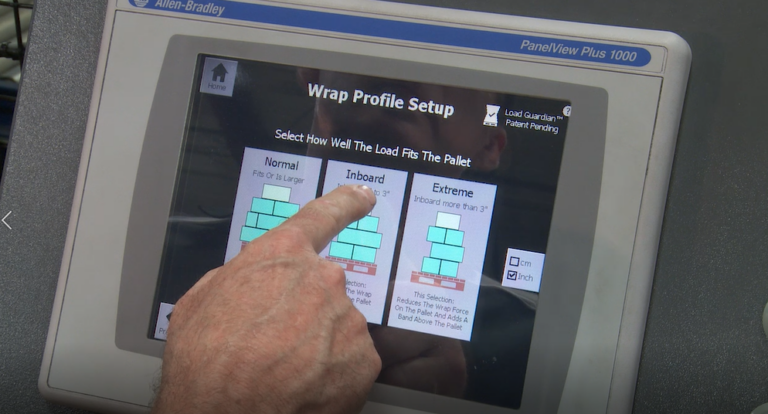

Load Guardian

Standard

Standard Film Width

500 mm (20")

EZ Thread Film Delivery

Standard

Standard Pre-Stretch

225%

Wrap Force

Variable (Electric)

Film Capacity

250 mm (10”) Roll Diameter

Film Delivery System

Power Roller Stretch Plus

NEMA Type 1 Enclosure

Standard

TurboTak®

Standard

Load Seeking Clamp 5.0®

Standard

Load Handling

Wrap Arm Drive

3/4 HP TEFC

Wrap Arm Speed

15 RPM

Wrap Arm Zone

2280 mm (90")

Weight and Size

Approx. Shipping Weight

1542 kg (3400 lbs)

Size

4801 mm L x 3810 mm W x 3073 mm H

(189" L X 150" W X 121" H)

Service Requirements

Pneumatic

5.5 Bar (80 Psi)

Dedicated Electric Service Required

240VAC/20A/1-Phase/50-60Hz

Warranty

Warranty Duration

3 Years, Unlimited Cycles, All Components Covered

Designed for AMR-Driven Automation

Lantech equipment is designed to integrate seamlessly with AMRs, providing a stable, predictable interface across stretch wrapping and case & tray handling operations. Our approach simplifies system integration with repeatable performance, clear machine communication, and layouts that support safe, uninterrupted AMR traffic. With proven experience in highly automated environments, Lantech helps reduce operator involvement, minimize downtime, and keep automated material flow moving.

- Predictable interface built for AMRs

- Consistent packaging results that support production planning

- Clear machine states for dependable AMR communication

- Designed for safe, uninterrupted automated flow