Sustainability at Lantech

At Lantech, sustainability isn’t a trend – it’s a responsibility.

Data-driven, practical and impactful

As the global packaging landscape evolves under regulatory pressure we are committed to delivering real solutions that reduce waste, optimize performance, and meet tomorrow’s packaging requirements today.

Our approach is data-driven, practical, and focused on making a measurable impact. From designing highly efficient packaging equipment to investigating the long-term viability of film alternatives, we help our customers meet their goals for environmental responsibility and operational excellence.

Why Sustainability Matters

Stretch film often accounts for less than 1% of the total weight or cost of a pallet’s packaging – but it plays a critical role in protecting loads and reducing product damage. Unfortunately, because film usage is rarely optimized today, many companies use far more than necessary.

That’s why we believe the path to sustainability starts with visibility and optimization. Our equipment and machine data tools empower users to optimize every pallet wrapped – ensuring loads are wrapped to the required Containment Force to ship successfully, using the least amount of film as possible. What’s measurable becomes manageable.

Global trends we’re watching

We closely monitor sustainability legislation and packaging trends across the globe, including:

- The EU’s Packaging and Packaging Waste Regulation (PPWR), is in the process of implementing an effective reversal to the reuse requirement for transport packaging.

- The growing reach of Extended Producer Responsibility (EPR) laws in the U.S., particularly in states like California, Colorado, and Oregon.

- Rising demand for post-consumer recycled (PCR) content and investment in reuse and recycling infrastructure.

This global insight shapes our strategy and ensures our customers are prepared – not surprised.

Introducing the Film Alternatives Project

The stretch film landscape is changing – and we’re leading the charge in understanding what comes next. Since 2020, our R&D team has conducted an ongoing investigation into wrapping alternatives and legislative trends, resulting in the annual publication of an independent, data-backed white paper.

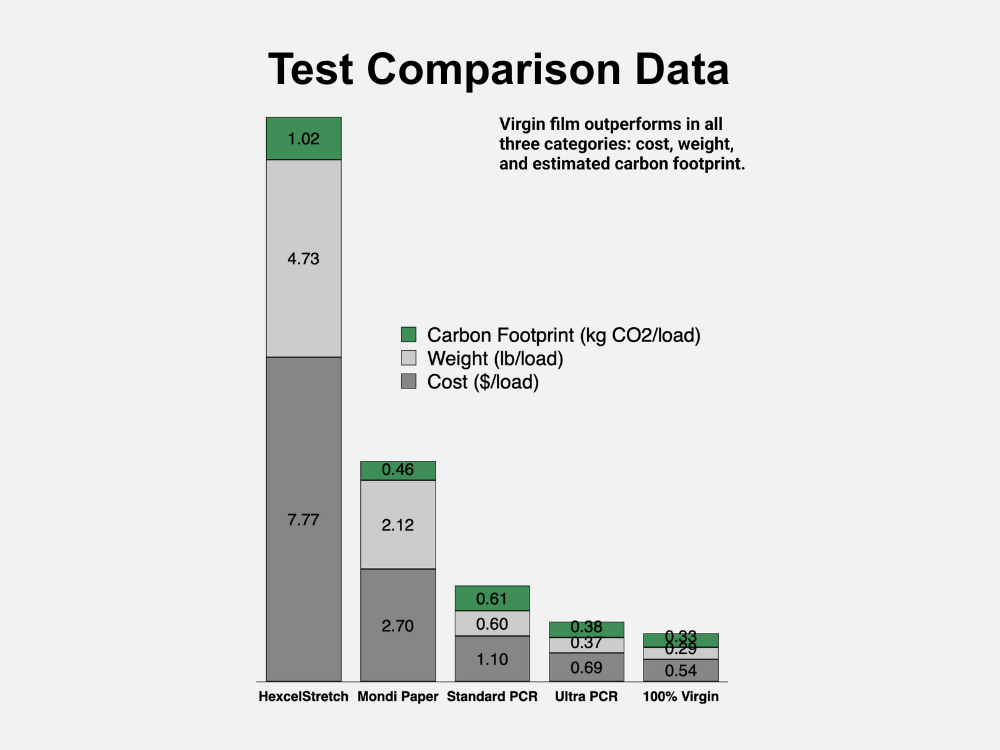

The Film Alternatives Project evaluates the performance and environmental impact of traditional, recycled-content, and alternative films. Some key findings:

- 100% virgin films are consistent, high-efficiency performers

- PCR stretch films fluctuate and introduce implementation risks

- The journey continues for recycled content

- Significant source reduction is still possible through optimization

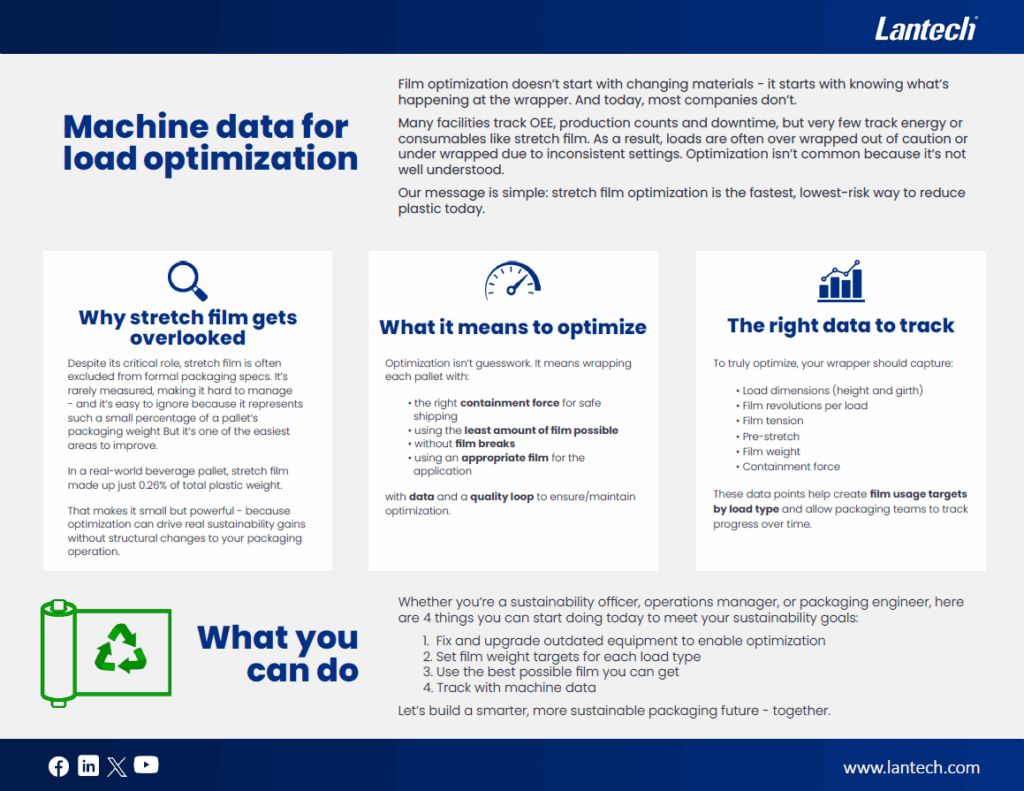

Machine data for load optimization

Film optimization doesn’t start with changing materials – it starts with knowing what’s happening at the wrapper. And today, most companies don’t.

Many facilities track OEE, production counts and downtime, but very few track energy or consumables like stretch film. As a result, loads are often overwrapped out of caution or underwrapped due to inconsistent settings. Optimization isn’t common because it’s not well understood.

Our message is simple: stretch film optimization is the fastest, lowest-risk way to reduce plastic today.