If you’re considering a case erector for your production line, wonder no more. Automating your case forming process might seem like a big leap—but the benefits speak for themselves. Whether you’re scaling up, struggling with labor shortages, or aiming to boost operational efficiency, a case erector delivers where it counts.

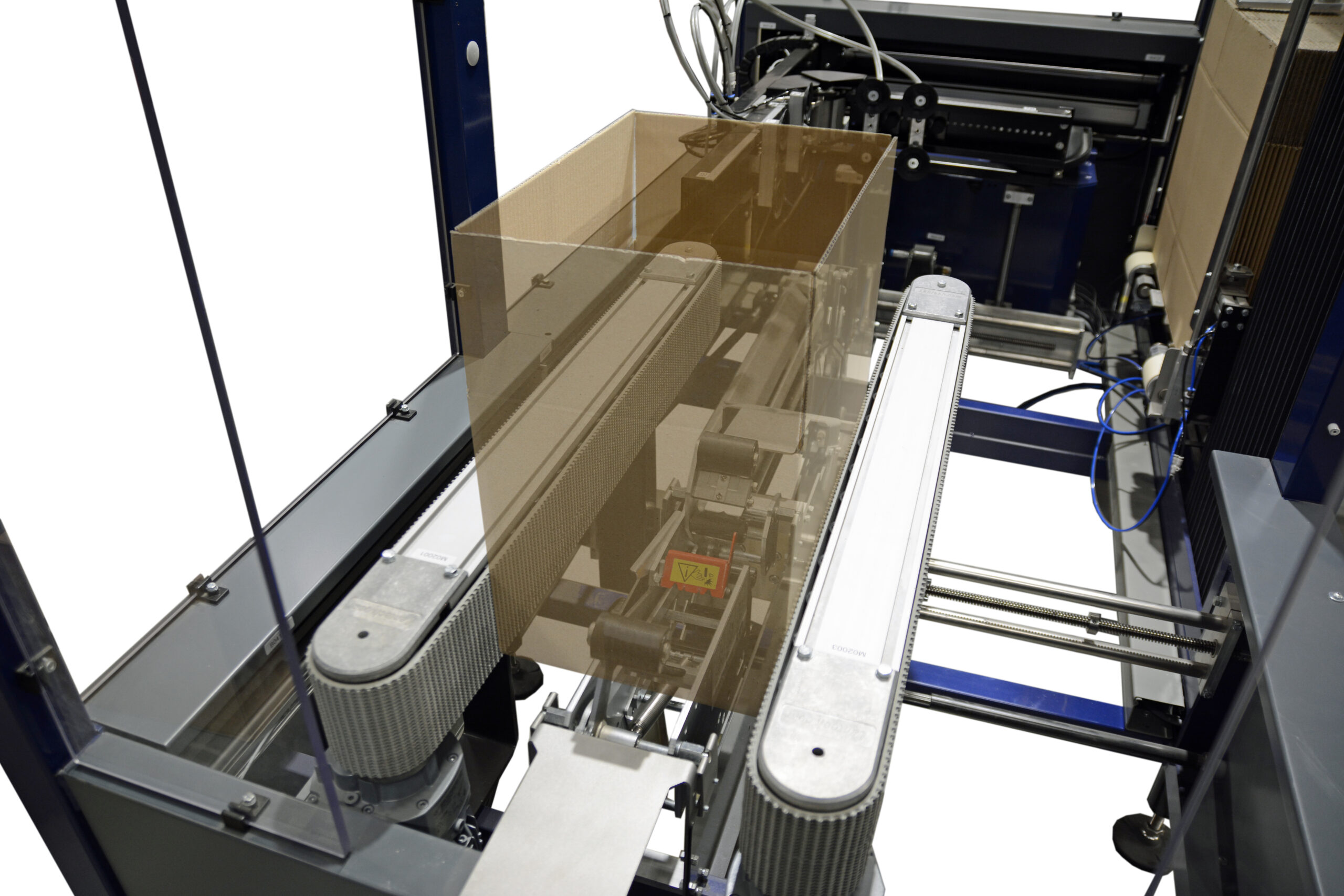

If you’re running a high-speed production or packaging line, but your case erecting process can’t keep up—causing backlogs, unplanned downtime, or costly labor interventions—then you’re not alone. Many operations struggle with inconsistent case forming that disrupts downstream flow and drains efficiency. Our case erectors are built for manufacturers and distributors who need reliable, high-throughput automation to eliminate bottlenecks and reduce manual handling. Whether you’re packing food, beverages, or consumer goods, this solution transforms a weak link into a seamless, high-performance part of your line.

Here are five powerful reasons to add a case erector to your packaging line—plus three big-picture advantages that show just how transformative this investment can be.

1. Increase Efficiency and Productivity

Manual case erection is slow. The average person can erect about three boxes per minute, while a basic automatic case erector can handle ten per minute—a 233% increase in speed. Higher-end models offer even greater throughput until 30 cpm.

Let’s put that into perspective: building 2,500 boxes by hand takes nearly 14 hours. A case erector cuts that down to just four hours, freeing up ten hours for other tasks.

This consistent output means fewer production bottlenecks, which is critical if you’re experiencing growth or trying to hit ambitious throughput targets. It also reduces your reliance on manual labor, which is a big advantage when skilled labor is hard to find.

2. Improve Case Quality and Stability

When boxes are formed by hand, quality is inconsistent. Some boxes are off-square or poorly folded, which can lead to:

- Unstable pallet loads

- Increased chance of shipping damage

- Downstream problems during filling or sealing

A case erector guarantees that every case is square, secure, and properly folded. That means stronger loads, better stackability, and fewer disruptions down the line. With consistently built boxes, you’ll also see a reduction in machine jams or issues with equipment like palletizers and sealers.

3. Reduce Labor Dependence and Strain

Manually erecting boxes isn’t just slow—it’s physically taxing. Repetitive motions can lead to strain injuries, and cardboard can cause surprising injuries (yes, even painful cuts from fresh edges). Automating this step eliminates a repetitive, injury-prone task and allows your team to focus on more valuable, less physically demanding work.

If you’ve been adding more people to the packing area just to keep up, a case erector helps your existing team work more efficiently—meaning fewer workers required, reduced overtime, and a better use of your labor force.

4. Free Up Floor Space and Reduce Inventory Waste

Many operations try to stay ahead of demand by pre-assembling dozens—or even hundreds—of boxes. But empty boxes take up space. A lot of space. That’s valuable square footage you’re paying to use for… air.

A case erector lets you shift to on-demand box production, freeing up storage areas and walkways. This supports lean manufacturing principles and reduces the waste of space, time, and materials.

5. Protect Your Products and Your Reputation

Poorly formed cases don’t just look bad—they perform badly. Misshapen boxes are more likely to collapse during shipping or damage the product inside. By delivering consistent, sturdy cases, a case erector helps you:

- Prevent product damage

- Reduce returns and damage claims

- Maintain customer satisfaction

When your packaging holds up, so does your brand reputation.

And the Bigger Picture: Why It Pays Off

Beyond these five core benefits, a case erector offers three strategic advantages that pay off over the long term:

Efficiency That Scales with You

As production volumes grow, a case erector scales right along with them—keeping pacewithout requiring additional staff or space.

Long-Term Cost Savings

You’ll reduce labor costs, minimize waste from tape or misused materials, and avoid costs associated with damaged goods and returns.

Improved Uptime and Reliability

With consistent, machine-formed boxes, downstream machines operate more smoothly—meaning less downtime and fewer malfunctions.

But What About Jams?

Yes, some case erectors are prone to jamming, which can cause frustration and downtime. The good news? Most jams stem from:

- Poor blank feeding in the magazine

- Irregular carton blanks from suppliers

- Weak or inconsistent mechanical opening and folding

- Trouble transporting the formed box

When selecting a case erector, look for models specifically designed to address these issues—with positive case control, intelligent blank separation, and robust mechanical performance.

Final Thoughts

A case erector may seem like an optional upgrade—but in reality, it’s a strategic investment. From boosting productivity and reducing labor reliance to improving box quality and protecting your shipments, the ROI is clear.

Curious how a case erector could transform your operation? Contact us or explore our buying guide to find the right solution for your line.