Why Lantech Automatic Stretch Wrappers

The Power of Technology

Lantech Automatic Stretch Wrappers run 24/7 in real world environments and are backed by our superior global after market support. They deliver more uptime and safe-to-ship loads, at a lower carbon footpring, than any other stretch wrapper on the planet.

Our relentless commitment to innovation and delivering superior value to our customers has led us to announce that we are upgrading and streamlining our Automatic Stretch Wrapper product line.

Lantech machines are built to keep running.

Our machines are solid, stable, strong and reliable and are designed to deliver the highest level of performance and productivity to help our customers achieve their shipping objectives.

Lantech Advantages

Our stretch wrappers are easy to use, safe and reliable.

Safe-To-Ship Loads

Lantech invented the concept of containment force and continues to innovate to help our customers wrap safe-to-ship loads every time!

Wrapping Safe-To-Ship Loads

Stretch wrapping has become the standard way to unitize products for shipment. But just because the load is wrapped and it’s shiny, doesn’t mean it’s ready for the back of a truck. Without proper stretch wrapping, loads can fail during shipment, causing damage to the product and damage to the brand.

It is estimated that ineffective stretch wrapping is responsible for over $70 billion of waste each year, just in consumer product goods. Now, more than ever, improving stretch wrapping processes, setting a standard and maintaining it is important in any shipping operation.

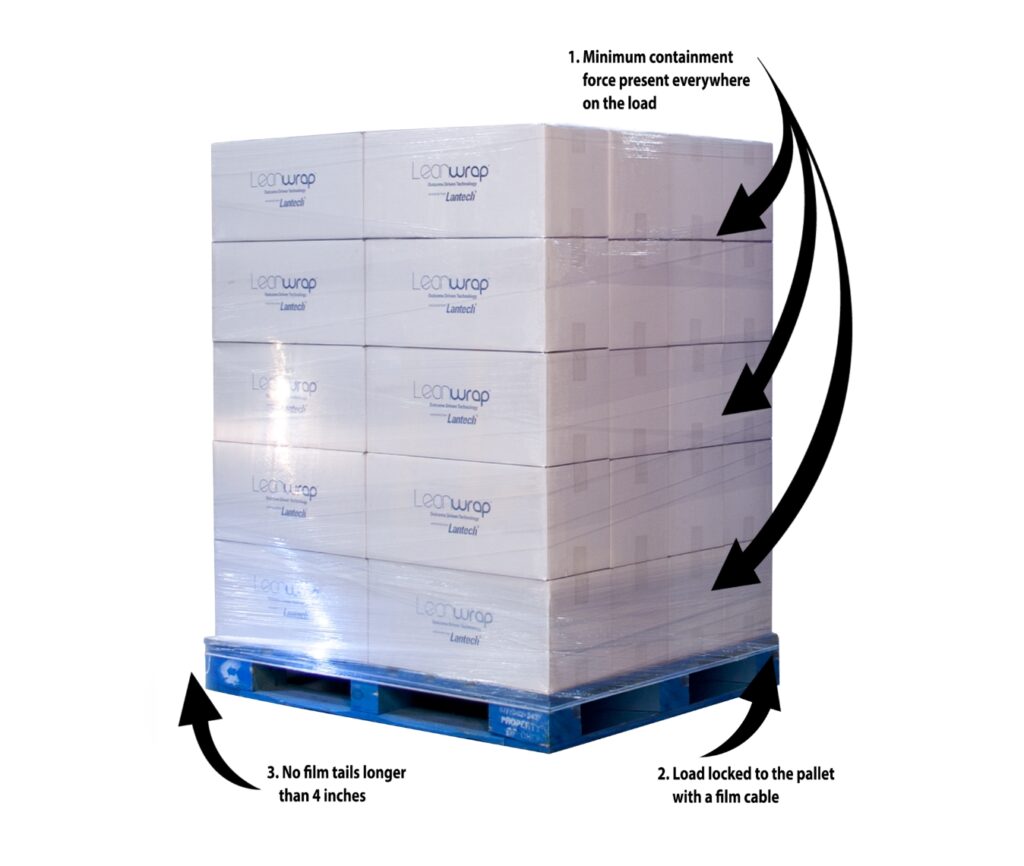

Three signs of a safe-to-ship load:

- There is enough containment force everywhere on the load.

- The load is locked to the pallet.

- There are no long or dragging film tails.

What Is Containment Force?

Containment Force is the total force applied to your load at a given point. Containment Force is produced by wrap force (tightness) multiplied by the number of stretch film revolutions. It’s the key specification in reducing damage and ensuring safe-to-ship loads.

“Experience has proven the value of measuring containment force. Established wrap parameters need to be confirmed to ensure load safety; doing so quickly and with a high degree of accuracy is essential in busy shipping operations.”

– Lantech Founder and Chairman Pat Lancaster

For more information, check out these related articles on Containment Force:

The right amount of Containment Force, everywhere on the load, is the primary indicator of a safe-to-ship load.

Make sure you periodically check your loads to determine if they fall within the guidelines. Use Lantech’s Containment Force Recommendation Chart to find the right value and the CFT-6 tool to measure.

Containment Force Tool™ 6, commonly known as the CFT-6, is our patented tool used to measure Containment Force. It provides fast, consistent, and nondestructive measurements of containment force on pallet loads. Order yours today!

LeanWrap Features

These features are designed to maximize productivity and performance, while delivering safe-to-ship loads. Available on select automatic stretch wrappers.

Pallet Grip®

Lock Your Load to the Pallet!

Don’t Risk More Than You Have To! Millions of loads slide off their pallets during shipment each year causing billions of dollars of rework and waste. If your load isn’t properly bonded or “locked” to its pallet, it can slide off and be damaged during shipment. Stretch wrapping all the way down to the bottom of the pallet isn’t enough. Puncture holes in the film – caused by the forks of a forklift or pallet jack – may spread up the load and jeopardize the containment force of the film.

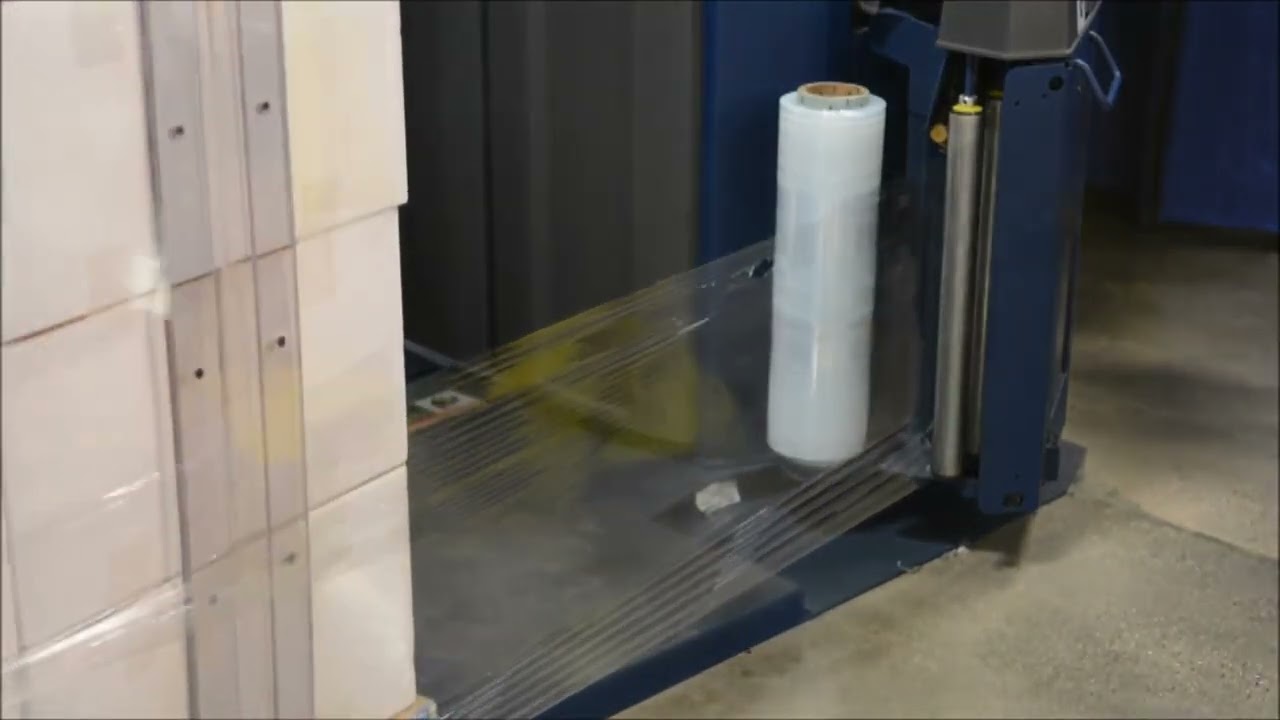

Metered Film Delivery®

Don’t use old technology to do today’s job!

Until now, Lantech’s Metered Film Technology used the girth of the load instead of the force on the film used by traditional force based systems. Our Metered Film Delivery was able to produce a higher containment force per revolution, resulting in better load containment with less film and fewer film breaks.

The next generation of Metered Film Delivery builds upon the current performance with precision control for all load sizes, maintaining a consistent force per revolution. This results in even fewer film breaks and lowering film consumption, which minimizes the downtime associated with stretch wrapping loads and helping to achieve lowest carbon footprint

Load Seeking Clamp®

Improve uptime, wrap quality and reduce film breaks!

A film clamp engineered specifically to reduce film breaks or film pull-outs at the start of the cycle, both significant sources of downtime. The clamp moves out to the edge of the load at the beginning of the wrap cycle to attach the film. It ensures the leading film tail is captured and has three times the holding force of conventional clamps. Because the Load Seeking Clamp moves out to the load, it prevents the “tenting” effect that happens with stationary clamps which reduces Containment Force at the bottom of the load.

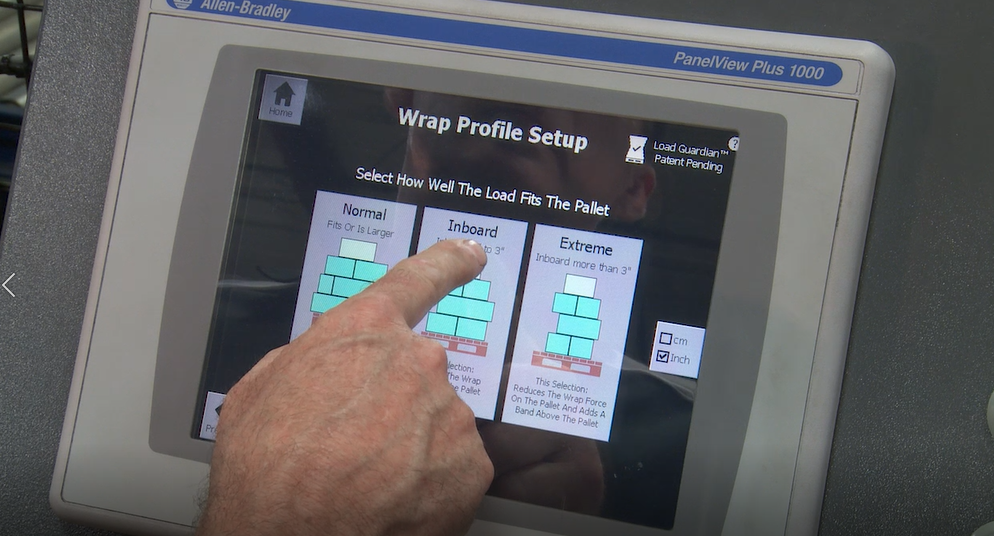

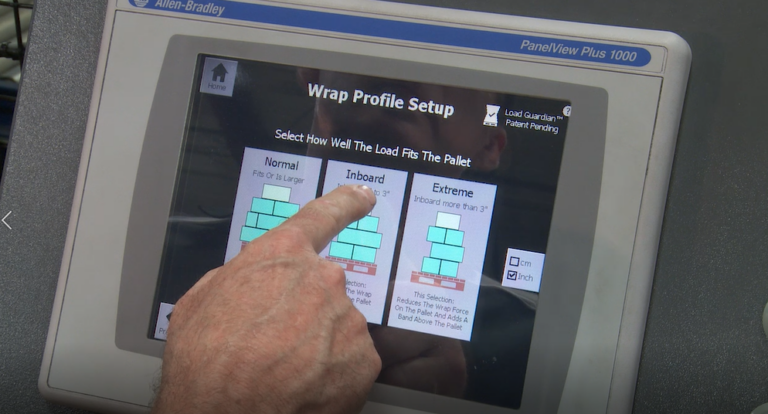

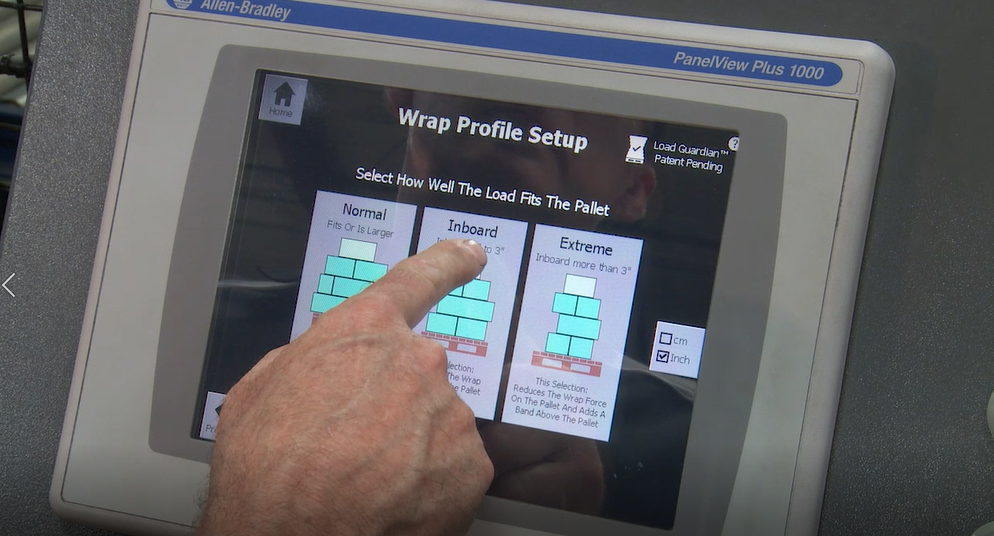

Load Guardian®

Create, maintain and deliver safe-to-ship loads every time!

Load Guardian® is Lantech’s patented control system that creates, maintains and delivers the right containment force for safe-to-ship loads every time. It minimizes operator interaction and eliminates the guess work for stretch wrapping any load configuration.

Load Guardian®:

- Creates and saves profiles (at start-up or whenever you need one).

- Maintains profile standards automatically.

- Delivers the right amount of containment force everywhere on the load, every time.

- Eliminates the need for operator skill and involvement.

- Produces a knowable and repeatable film cost.