Note: This blog post has generated so much attention that we’ve decided to run it one more time.

Note: This blog post has generated so much attention that we’ve decided to run it one more time.

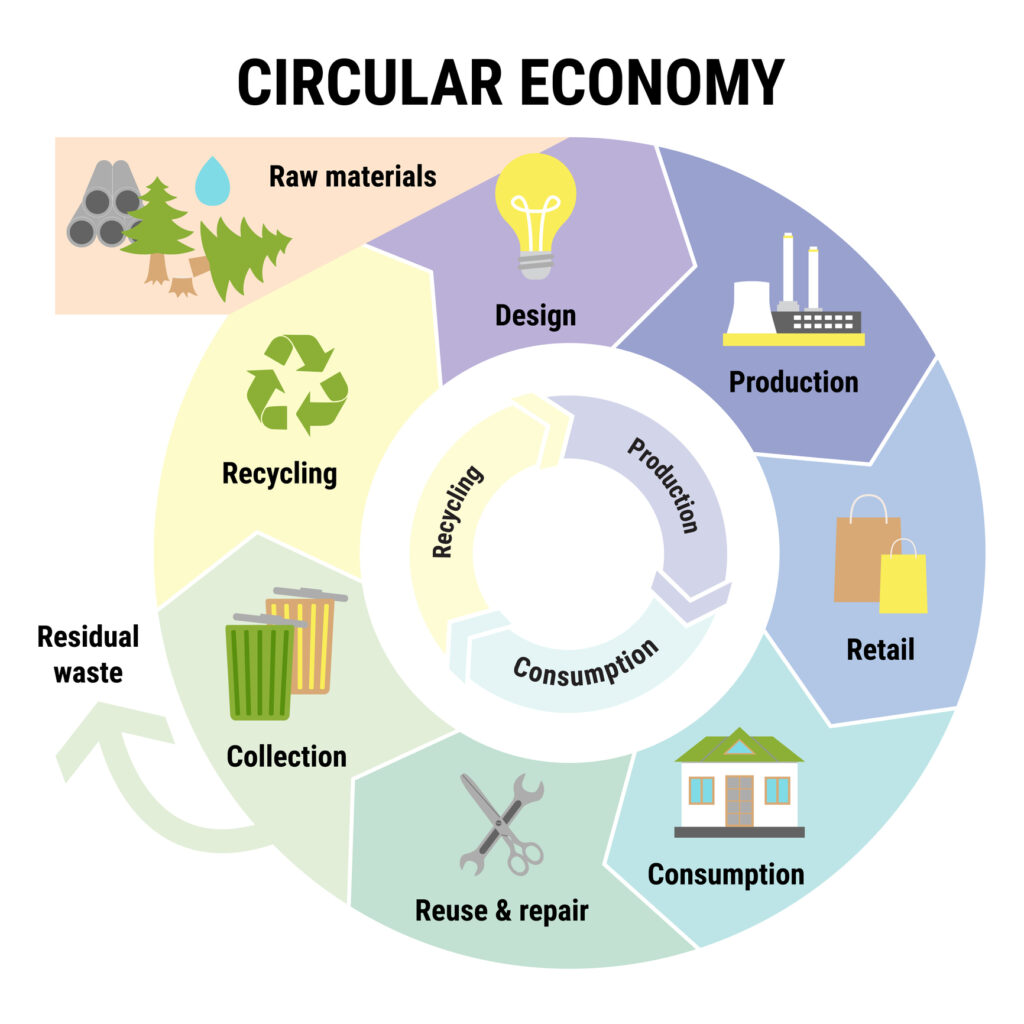

We’ve talked about Lean Manufacturing quite a bit on our blog, but we haven’t really discussed all the principles of it, or what it all means. For the most part, we’ve talked about muda (waste), and how to identify and eliminate it.

There are actually five foundational principals to the Lean philosophy. While it’s used primarily in manufacturing, we’re starting to see service providers use this kind of thinking as well.

Lean doesn’t actually mean “going without,” although many people think so. Rather, it’s an organizational philosophy that’s similar to the writing philosophy “write down the bones,” in which you omit needless words like adverbs and adjectives, or use the active voice instead of passive. Lean means eliminating waste and finding the simplest, most efficient way of doing the work.

Here are the five foundational principles of Lean:

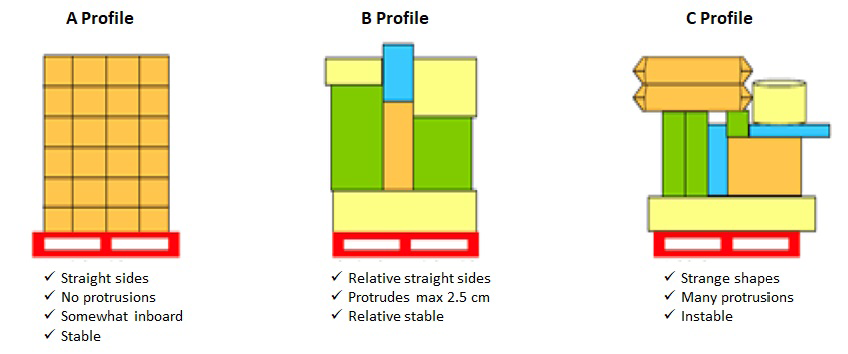

Identify Value: Only some of what a company does actually brings value to the end customer. For example, a product that’s free of defects brings value, while weekly staff meetings do not. Reduced shipping damage brings value, monthly TPS reports don’t. Eliminate the things that do not add value.

Map the Value Stream: The value stream is all the activities within the organization that are involved in delivering your products. By mapping it out, you can identify all the areas that do and do not deliver value to the customer. Enhance the things that do, eliminate the waste that does not.

Create Flow by Eliminating Waste: Flow is achieved when all parts of the value stream (manufacturing process) can continue without interruption. Interruptions are usually bottle necks and breaking points within the process. When these interruptions happen, waste (Muda) occurs. Eliminate the Muda, you continue to maintain flow. But this is easier said than done, and it’s an ongoing process.

Establish Customer Pull: As your customer continues to tell you what they want (pull), you need to work your process around that. Produce only what the customer wants when they want it. This means no over-processing or over-producing (two of the seven mudas). Listen to your customers and develop good relationships with them. Let your customers ultimately define what you’ll do and how you’ll do it.

Pursue Perfection: Identify where the value lies, eliminate waste, create ongoing flow and streamline processes until you get them right every time. Make this the standard operating procedure, and not just “a good day.” While you may not actually achieve perfection, you should still strive for it.

We’ve managed to condense the five basic principles of Lean thinking to a single blog post, and made it sound much easier than it is. Our goal is to give you a place to start and to learn more about this philosophy that’s revolutionizing processes all over the world.

Start with the first principle, identifying value, by doing a self-evaluation. Do a simple walk through of your daily routine. Look for times when your activity isn’t bringing value to your customer. Look at wait times, rework times and constraints. We’d like to hear about your findings. Tell us about an activity you’ve identified as non-value added and what you did to reduce or eliminate it.

For more information, you can contact us on our website or call us at (502) 815-9109.

Click here to read related blog: Use a PDCA Loop for Accomplishing Goals

This post was published on April 30, 2014 and updated on November 28, 2018.

April 30, 2014