Most stretch wrappers come with manuals on how to operate and trouble-shoot the machines. But they barely begin to cover what you need to know to create a safe-to-ship load.

Most stretch wrappers come with manuals on how to operate and trouble-shoot the machines. But they barely begin to cover what you need to know to create a safe-to-ship load.

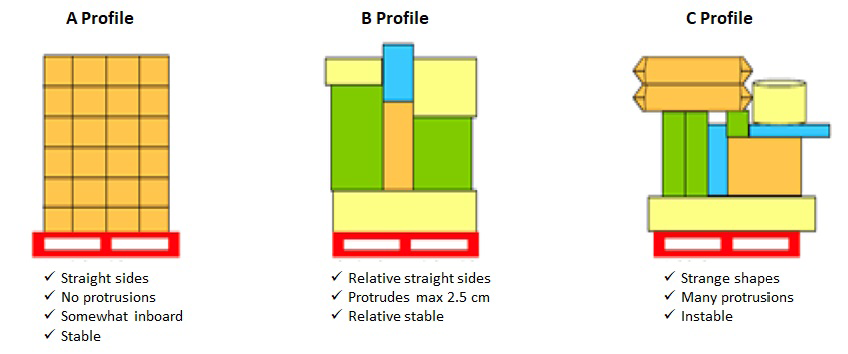

Containment force – the holding force of the film around the load – is the most important factor in shipping successfully. It’s determined by the wrap force multiplied by the number of film layers around the load. Every load requires its own unique amount of containment force, depending on the load shape and product.

We’ve compiled 15 tips around containment force, film breaks and machine settings that we hope you’ll find useful when establishing a safe-to-ship load.

Containment force tips:

- Buy a containment force measuring tool with your stretch wrapper. This tool will measure the film force in pounds on the load. Click here to figure out how much containment force you need.

- If you don’t have a containment force tool or know how much containment force you need, wrap as tight as you can without twisting or crushing the load and without breaking the film.

- There are a number of containment force measuring tools and methods available. Be sure you know which one you’re using and that its measurements will not be directly comparable with those from other tools.

- Even when using the same tool, there can be considerable person-to-person variation in measurements. Round up. It’s better to have more containment force then you need than not enough.

Film tips:

- Don’t cheap out when buying stretch film. “Bargain” films are false economies. Product damage is a much bigger stretch wrapping cost driver than film cost. Get a good film. It’ll wrap better and run better. The goal of stretch wrapping is not to minimize film cost. Getting the right containment force at the lowest film cost is what you want to do.

- Operators overcome film breaks by reducing the force at which it’s applied to the load. This results in lost containment force unless they compensate by adding more layers of film. They often neglect to do this, increasing the probability that something bad will happen to the load during shipment.

- Generally, the thinner the film, the lower the wrap force at which it can be applied without excessive film breaks. There is a point of diminishing returns on film gauges and pre-stretch levels. Be careful when choosing these. Better to err on the high side.

- Most loads are wrapped with more containment force (more film) at their tops and bottoms and less in the middle. If there are no damage or shipping problems with these loads, the amount of containment force in the middle is sufficient for the entire load. This often leads to an opportunity to reduce the film at the top and bottom and lower costs.

- If you’re not sure where to start, try a good grade 70 or 80 gauge stretch film pre-stretched at 200 percent. This combination provides a good blend of wrap quality, minimal film breaks, and acceptable film cost for a wide variety of load types.

Settings tips:

- When adjusting the wrapper for a new load, start with the turntable or wrap arm speed. Work up to a speed the load can handle. Restacking fallen loads isn’t fun.

- Then set the top and bottom wrap counts and the film overwrap at the top of the load (number of inches the film extends over the load’s top). Begin with “2” for the top counts and “2” for the bottom.

- Next, adjust the film delivery system up and down speed. Start with a 6 in. overlap of film bands.

- Finally, adjust the wrap force. Apply as much force as you can without breaking film or twisting or crushing the load.

- Measure containment force at the load’s top, middle and bottom with your containment force tool. Make sure it meets or exceeds the load’s containment force requirement. Adjust the settings and repeat the previous four steps until you get the right containment force.

- Optimizing the wrap pattern, film type and gauge, pre-stretch level, film delivery system speed and wrap force setting is hard work. Really hard! Really tedious. And takes time. Don’t expect to do it in 30 minutes.

To learn more about how semi-automatic stretch wrappers can help you create a safe-to-ship load, go to lantech.com.